Required distance between air conditioner units: basic rules and regulatory installation requirements

During the installation of air conditioners, it is important to take into account many aspects, including the manufacturer’s recommendations.Agree that a properly installed unit works more efficiently and its service life is much longer.

Technical conditions include the choice of the length of the freon route of the split system - a copper pipeline connecting the internal and external modules. There are boundaries, violation of which leads to a sharp decrease in productivity and breakdown of key components.

In this article, we will consider what the required distance between air conditioner units should be and find out whether it is possible to increase the length of the connecting line without loss of functional qualities.

The content of the article:

The principle of operation of the split system

First, let's find out how a household split system works - this will make it easier to understand why installation nuances are important.

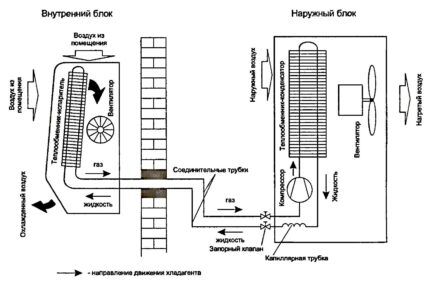

As you know, a home air conditioner of a traditional design consists of two blocks: one of them is installed in the room, the second is fixed outside, on the outside of the wall, in the attic or in any other place..

The process of cooling the air in the room occurs due to the continuous movement of freon and its transition from a gaseous state to a liquid state, and then vice versa. When the refrigerant is in the gaseous state, it absorbs heat, and in the liquid phase, it releases.

The condensation process, that is, the transition to a liquid aggregate state, occurs at high temperature and pressure, and boiling, at which the gas evaporates, is characterized by low values.

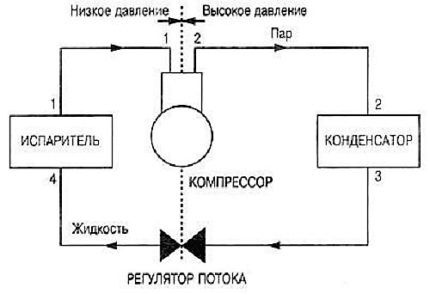

The heat exchange process occurs as follows. The compressor sucks steam from the evaporator (zone 1-1), compresses it and sends it to the condenser (zone 2-2). In this case, the refrigerant is compressed to 20-25 atm, and its temperature rises to +90 °C. Cooling and condensation occur there.

From the air conditioner (3), the refrigerant, already in a liquid state, returns through the flow regulator under low pressure conditions to the evaporator (4). The internal air heats the liquid, boiling and turning into steam. And so the process repeats endlessly.

The transition of the refrigerant from one state of aggregation to another occurs both in heat exchangers and in pipes. In order for the process to start and finish on time, a certain length of the line is necessary - which is why it is important to take into account the length requirements established by the equipment developers. With device and operating principle of a typical air conditioner We figured it out, and now we move on to the norms and rules for installing its blocks.

Freon line length

Users of climate control equipment often argue about the distance from the external unit of the air conditioner to the internal one, and then experiment with the installation. They can be understood - sometimes the features of the interior or the location of rooms require an increase in the length of the pipeline.

But professional installers know for sure that it is impossible to increase or decrease the length of the pipeline without permission. Indeed, deviation from the required parameters immediately affects the performance of the air conditioner.

Let's find out what the installation standards should be and why they cannot be changed.

Distance standards between blocks

Installation standards are set by the manufacturer. If you take the instructions, in the installation section you will find diagrams and operating parameters that you need to focus on during installation.

As a rule, the maximum length of the highway is indicated, nothing is said about the minimum. But complete with the blocks you will find copper tubes for connecting them - they should not be shortened under any circumstances.

The length of the pipeline depends on the model.

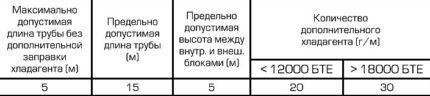

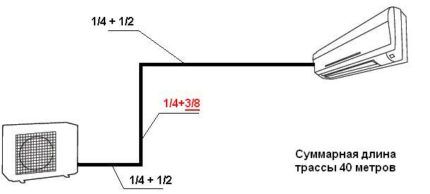

For household split systems with an internal wall unit, the following standards apply:

- maximum distance between blocks – 15 m or 20 m (less often - 10 m);

- minimum distance between blocks – 3, 4, 5 m (according to the length of the pipe included).

The exact data is indicated in the technical documents for the specific model.

Based on the parameters indicated in the table, it is clear that when extending the route, additional filling of the circuit with freon is required.

If the split system is equipped with a 5-meter pipe, it cannot be shortened. What to do if the distance between the blocks is only 3 m, and the tube is 5 m? You just need to carefully wind it up in large rings, without breaking or twisting, and hide the remaining 2 m in one of the blocks.

Pipeline too short

If manufacturers do not indicate the minimum length of the freon line in any of the available sources (paper or electronic instructions, video), rely on the generally accepted value - 3 m. The route cannot be made shorter.

If we remember how the process of transition of a refrigerant from one state to another occurs, we will understand that a short pipe is simply not enough to completely transform the substance. Freon, which has not had time to turn into gas in the evaporator, will enter the compressor in the form of a liquid, which should not be allowed.

The consequences of installing a pipeline that is too short are different:

- breakdown of air conditioner parts;

- transition of vibrations from the outdoor module to the wall module;

- noises uncharacteristic for an air conditioner - gurgling of freon in the pipeline.

The listed troubles can only be eliminated by increasing the length of the pipeline. As you can see, a small installation nuance turned out to be very important.

Distance longer than standard

As you already know, the maximum length of the freon line is limited to 20 meters. This value is relevant for home models with an average productivity of 2.5-3 kW. But for semi-industrial units from 8-9 kW, other limits are used - the pipeline length increases to 50 m.

We can conclude that the parameters of the distance between the blocks of split systems are directly related to such technical characteristics as productivity.

The most dangerous thing that can happen if the pipeline is too long is a decrease in pressure. Moreover, negative consequences await both sections - gas and liquid.

If the gas pressure drops before it enters the compressor, it also becomes lower at the outlet. As a result, temperature parameters decrease and freezing occurs.

There is no special line heating function, so the compressor overheats and breaks due to the load. You discussed the features of compressor diagnostics and how to repair it in the article: How to lay an air conditioner route: specifics of the communications device

A decrease in pressure in the pipeline section with liquid freon leads to an increase in the proportion of gas. A high gas content increases the speed of movement of the refrigerant, which leads to an even greater drop in pressure. In such conditions, normal operation of the air conditioner is simply impossible.

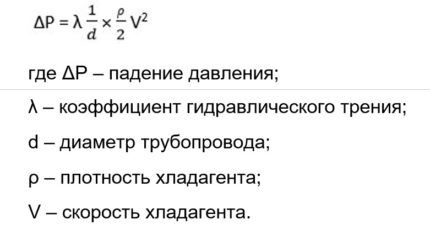

But there is one way out: to reduce pressure losses in the line, increase the diameter of the copper pipe. To do this, use the formula:

Professional installers advise increasing the length of the freon line only in horizontal sections.

In order to avoid complex calculations, it is recommended to increase the diameter of the gas pipe (it is slightly thicker) by 1 size: that is, replace 3/8 with 1/2, 1/2 with 5/8, etc.

We do not recommend doing the usual installation of an air conditioner or replacing pipes yourself. Experienced specialists know better what to do in difficult cases and avoid problems.

Height difference between blocks

In addition to the length between the split system modules, a certain height difference must also be maintained. It is always indicated in the instructions and for household models it is usually no more than 5 m, less often - 10. Large values are typical for semi-industrial and industrial models - up to 20-30 m.

If the length of the freon route can be slightly increased, then experimenting with height is prohibited. For this reason, the outdoor unit is most often installed 2-3 m below the wall module.

Owners of city apartments have a small choice - next to the balcony or window. Owners of one-story cottages sometimes install an external module directly on the ground, on special supports. We talked in detail about choosing the optimal location for installing the air conditioner in this article of ours.

Conclusions and useful video on the topic

An example of choosing the installation location for a split system in accordance with the manufacturer’s requirements. Installation Basics:

Errors when reducing route length:

It is much easier to install it yourself or supervise someone else’s work if you know the principle of operation of the equipment and the intricacies of installation. As you have seen, choosing the length of the freon line is not a whim, but a technically verified condition for the correct operation of the split system.

We do not recommend deviating from the parameters specified by the manufacturer. But if there is no other way out and you need to increase the length of the pipeline, be sure to contact a specialist.

At what distance are your air conditioning units installed? Tell us about your personal experience in choosing a place to install blocks outside and inside the building. If you still have questions about the topic of the article, do not hesitate to ask our experts and other site visitors - the feedback block is located below.

Hello, is the length of the freon line and the differences between the indoor and outdoor units the same for inverter split systems?

Almost without question, except that when laying long lines it is also necessary to ensure the return of oil to the compressor, otherwise if you lay 15 meters horizontally so that the middle sags, you will add kilograms of freon

Hello. Is it possible to install an outdoor unit 1-2 meters higher than an indoor one?