How to make shelves and racks in the garage with your own hands - options, instructions, photos

A garage is not just a building where you store your own car. It has several functions - it is a small workshop and a small warehouse.If you build a basement under the garage, the functionality of the room increases several times.

But in order for all the functions to work, you need to start arranging the room. For example, install shelves in the garage that will be used as storage space. And the more shelves, the more everything will fit on them.

The content of the article:

What design should be

There are several requirements for shelves and racks for tool, accessories and other things. They must be strictly observed:

- Shelves or racks must fit the size of the garage. Their presence should fulfill one task - to organize the space so that tools and things do not interfere with parking the car, so that a person can find them at any time. The dimensions of the garage shelves should be such that they themselves do not interfere. If there are not many tools, canisters, jars and others, then several shelves solve the problem. If there are a lot of them, then you can’t do without a rack.

- Shelves must be reliable and stable. Therefore, you first need to decide what will be stored on them. For example, if these are small tools, fasteners and other small things, then you can get by with wall shelves. If you need to store tires, filled cans, large and heavy objects in the garage, then you need to build a large rack (also known as a floor shelf) in the garage. The larger the structure, the more expensive it will cost.

- Safe operation. A garage is a high fire hazard facility. Therefore, the best material for building shelves is metal.Wood is also suitable, but it will have to be treated with fire retardants. Shelf surfaces must be non-slip. A collar on the outer edge will increase safety. The structure should not have sharp protruding elements to avoid injury from them.

- Ease of use. The number of shelves and racks, their sizes, and location should satisfy the owner of the garage. But to do this, you first need to decide what materials, tools, etc. will be stored on the shelves. Then you can draw up a diagram.

First of all, you need to decide on the size of the shelves and their locations. Therefore, it is recommended to draw up a drawing of the garage, where you try to find a convenient place to install them, taking into account the area that the car occupies.

Options for shelves and racks

Today, manufacturers of industrial furniture offer many different designs, shapes and sizes of racks and shelves for the garage.

Classification:

- Stationary floor shelves in the form of a bookcase. This design is called a rack. This is the most reliable option, because it is attached to walls, floors, and sometimes even to the ceiling. This model cannot fall over, which ensures safety of use. Often, a large number of attachment points are made on the racks of the structure, which allows you to rearrange the shelves, increase or decrease their number. The load-bearing capacity of such objects is high. You can store heavy objects on them. They are usually made of metal, but the shelf can be made of wood.

- Collapsible shelves. This is a bookcase that you can assemble and disassemble with your own hands - the connection points of the elements are so simple. Usually shelves of this type are small in size, their load-bearing capacity is low, and their strength is also not high.Used for small equipment. Made from metal profile.

- Mobile shelves. Wheels or rollers are attached to the lower ends of the support posts, allowing you to easily move the rack. On the one hand, it is convenient, for example, to bring a whole arsenal of tools to the place of car repair. On the other hand, the model has low stability.

- Rotating. Such shelves have recently appeared in Russian stores. Usually small things are stored in them. They are not intended for large or heavy items. Rotation ensures accessibility to everything on the shelves. If the garage is used as a workshop, then this option is very convenient. Manufacturers offer floor-standing and table-top models.

- Island. This is a subtype of mobile rack that can stand on wheels or without them. It is small in size, lightweight, and has 2-4 shelves. The load-bearing capacity is weak, but it is a good option for hardware, small tools, including electrical ones.

- Modular. The structure consists of several modules that fit together. You can build up shelves indefinitely.

In addition to everything indicated, manufacturers offer hanging shelves and drawers, rails, grilles and other products in which you can store tools, equipment, fasteners and oversized items. They can be straight or angular, and you can hang the shelves on the walls or ceiling. This is where convenience is at its maximum.

Instructions for making shelves yourself

The complexity of manufacturing depends on what material the homemade garage shelf will be constructed from. If it is a metal profile, then the worker must have the skills to work with an electric welding machine, power tools and other equipment. All these units must be available.

If the shelf is made of wood, the process is simplified because welding and other complex technologies are not necessary to connect the parts. Everything is attached with self-tapping screws. Therefore, next we will talk about how to make shelves for a garage out of lumber with your own hands.

This will be the cheapest design, which is inferior in operational safety to its metal counterparts. But in order to increase this criterion, it is necessary to treat wooden elements with antiseptics and fire retardants - in exactly that order. Afterwards the rack is painted or varnished.

What you will need

To build a floor shelf in the garage you will need:

- timber with a section of 50x50 mm;

- boards 20-35 mm thick, 100-200 mm wide;

- metal mounting angles;

- wood screws;

- sandpaper;

- protective impregnations;

- paint or varnish.

But in order to determine the amount of materials required, you need to know exactly the dimensions of the garage shelf. The height should be equal to the height of the garage. This makes it possible to place more shelves in the same area.

Depth requires balance. Because deep shelves take up a lot of space, but on the other hand they are more spacious. Therefore, everyone has their own thoughts in this regard, hence the wide size fork - 30-80 cm. But if the shelf is intended for large items, then the maximum size is taken, and vice versa.

Taking into account that a 50x50 mm beam is chosen for the racks, the length of the shelf should not exceed 1 m. For example, if the length of the garage is 4 m, then you can use 2 options:

- Make 4 shelves 1 m long and connect them together.

- Use a larger cross-section of timber not only for the racks, but also for the frame of the shelves. This will increase the cost of construction.

The next dimensional parameter is the distance between horizontally laid shelves. There is no standard here, it can be any size. As a recommendation – 30-50 cm.

What tools you will need:

- wood saw;

- screwdriver;

- pencil and tape measure;

- metal ruler;

- construction corner;

- paint brush;

- paint tray.

Step-by-step instruction

Initially, you need to make a shelf, for example, 1 m long, 50 cm deep and 2.5 m high. And you need as many such racks as will fit the length of the garage. First of all, following the instructions, you need to cut the racks and frame elements.

The height of 4 racks is 2.5 m each. They need to be cut from prepared timber 50x50 mm. Parts of the frame structure are cut from the same material, on which the boards that form the shelves will be laid. Therefore, you need to decide on the distance between the latter. For example, the same 50 cm. This means that you will need 4 frames, the bottom of which is installed at a height of 50 cm from the floor.

The elements of the frame structure are 2 bars 1 m long, equal to the length of the rack, and 2 bars 50 cm long, equal to its depth. Since there are 4 frames, it means that you need to cut 8 elements of 1 m each - this is 8 m, and 8 of 50 cm each - this is 4 m. Plus the length of the racks - there are 4 of them of 2.5 m each, that is 10 m. In total you need 22 m .

Depending on the length of one rail, you can calculate their number. For example, if the length of one bar is 4 m, then: 22:4 = 5.5 pcs. You'll have to buy 6 pieces.

First of all, you need to make frames for the shelves themselves. This is a rectangular structure of 4 parts: 2 beams 1 m long, 2 50 cm each. They must be laid out on a flat surface: floor, workbench, table, accurately reproducing the rectangle. Here you can use a construction corner to align the right angles between the joined elements.

All bars are connected to each other with steel fastening angles and self-tapping screws. For example, like in the picture below.

There is another type of corner. They are also reliable fasteners. But to use them, the edges of the bars must be cut at 45º in order to join at a right angle. In this case, the corner is laid along the end surface of the two joined elements. This can be seen in the photo below.

You can do without corners. Simply fastening is carried out with long self-tapping screws (at least 80 mm), which are screwed into the ends of the bars being connected. There are 2 screws in each end.

The racks are cut to the required dimensions for the height of the future shelf, and the frames for the horizontal stands are also ready. All that remains is to assemble them into a single structure.

It is necessary to lay 2 racks parallel to each other on a flat surface. Mark them at one end with a pencil at a distance of 50 cm. Attach one finished frame to them and secure them together with the same steel fastening angles. It is better to install fasteners under the frame structure, so that the corners additionally serve as a supporting shelf.

In the same way, every 50 cm, the remaining 3 structures for shelves are installed and attached to the support posts. All that remains is to attach the remaining 2 racks to the semi-finished bookcase. They can be laid directly on top of the structure lying on the floor and attached to the frames with corners using self-tapping screws. You can do the opposite: place a half-finished rack on supports laid parallel to each other, and turn it 180⁰.

The multi-level garage shelf is ready. It must be treated with an antiseptic composition that will protect the wood from mold. When the impregnation dries, a fire retardant compound is applied. It should dry out too.Next, the entire structure is covered with paint or varnish.

This is how all the shelves are made, which are connected to each other either directly with self-tapping screws, or with perforated inserts in the form of a piece of tape. The latter are also fastened with self-tapping screws.

There is another option that will help you assemble a shelf in a stationary garage. It will be firmly attached to the inside wall of the garage. To do this you will need a board with a section of 30x100 mm. It is attached to the wall horizontally at levels every half meter. For example, it will be 3-4 boards the entire length of the garage wall.

Next, assemble a structure consisting of the same boards, laid every 50 cm on racks from the same board. The distance between the supports is 1-1.5 m. The result is a grid with cells 50x100 cm. It must be placed vertically at a distance from the wall equal to the depth of the garage rack.

Next, connect it to boards attached to the wall with crossbars made of the same material with a cross-section of 30x100 mm. Cross members are installed at each rack along its entire height at the level of horizontal elements. The fastening is the same - steel corners with self-tapping screws.

This is an economical option because there are no wall racks. But at the same time, this type of rack cannot be moved without completely disassembling it.

The last step in building garage shelves is installing the decking. Here you can use boards, plywood, OSB or chipboard, sheet iron, corrugated sheets and even plastic panels. Any flat material will work here.

You can use a metal mesh. You just need to choose based on the load that a particular material can withstand. In this case, the flooring itself can be attached to the frame or laid without fasteners. If boards or panels are selected, it is better to secure them.

We bring to your attention the article - DIY shoe shelves.

Helpful tips for planning your garage space

Where to put the shelf, how to distribute inventory and tools on it - there are many questions. Therefore, a few recommendations:

- The best place for the shelving is on a long wall in the garage.

- If the garage owner often uses some tools or other things, they should be placed on shelves located in a convenient place.

- It is better not to store containers filled with liquid substances on the upper levels. May fall, spill, damage the vehicle or injure a person.

- If there are a lot of hand tools in the garage, then it is best to allocate one large area for them. They can either be arranged in positions, or holes can be made in the bottom where these tools are inserted.

- It is better to store car tires on the floor. To do this, the flooring on the lower stand is removed.

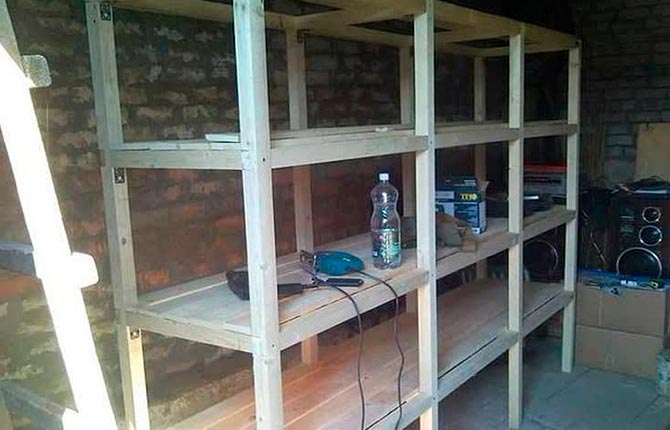

Photo options for arranging shelves in the garage

You can arrange shelving in a garage in different ways. The main thing is that the entire space is convenient to use. Here are some interesting options.

A very convenient option in terms of forming several zones along the wall at once. There is a workbench here, shelves above and below it. Wide pencil case, which will include almost the entire arsenal of tools. Plus - a large open cabinet for home scrubs, which did not fit in a house or apartment.

Another option with a workbench, but small in size. Made from profiled pipe by welding. A storage system for tires, tools and fuels and lubricants has been thought out. Everything is compact, convenient and reliable.

Corner option for a garage, where a wooden workbench is equipped with lower niches. Which is convenient.An open corner shelf is attached to the top of the wall - a simple structure made of flooring, metal brackets, and many hooks adapted to accommodate tools. The option is inexpensive, also compact, but functional.

Another corner type is a suspended model made of boards and pipes. These pipes are called furniture pipes. They have a thin wall, but the load-bearing capacity is surprising. The same fittings are sold for them (bends, tees, etc.). You can assemble any structure from pipes to suit the size and shape of the garage. They can be wall, floor, corner and others. Material convenient for self-production.

Surely some of the readers made garage shelving themselves. Share your experience in the comments - what you collected it from, what form you chose, what difficulties you encountered.

It’s better to spend money and make metal garage shelves. Will last longer, durable, stable. When I built a garage, I made shelves from scrap lumber. They served for five years. They turned black and oily. In general, the view was depressing. The paint did not adhere to them, it fell off in layers. In short, I threw it away and made new ones from a profile pipe. I think that's enough for my lifetime.

I once made a shelf for shoes in the hallway. I used furniture pipe. We still use it. Now you remind me of this. I'm thinking about replacing the old shelving in the garage with a new one made from this pipe.