Clamps for fastening pipes: overview of types and installation instructions

Fastening by installing a clamp is one of the most accessible and inexpensive ways of fixing a pipe to a structure or support. With their help, it is easiest to achieve a strong and reliable fixation of the pipeline.To choose the right device, you need to know what options the market offers. Do you agree?

We will tell you what you should pay attention to when choosing pipe clamps. The article we presented describes in detail how to choose the best option and how to install it. The technology is described in detail and recommendations are given, adherence to which will ensure an ideal result.

The content of the article:

Types of pipeline fasteners

According to the principle of fixation, the pipeline can be attached to the support either rigidly or freely.

The rigid rigid mount is designed for maximum loads. It is chosen when installing “cold” pipelines and strengthening them in places where there is a high risk of structural damage.

To fasten elements subject to thermal expansion, devices with floating mounts are chosen. They give the structure minimal mobility in the axis direction.

Fixing the pipeline with a clamp is achieved by tightening the pipe body with fasteners, the role of which is performed by locks, threaded pairs or worm mechanisms.

Regardless of the type of fixation, the use of clamps makes it possible to relieve the pipeline, thereby reducing the likelihood of damage to its individual sections under the weight of its own weight and vibration flows arising during movement.

According to the material of manufacture

The main requirement for the materials used in the manufacture of the clamp body is high mechanical strength. After all, the body of the product is designed to provide points for transmitting mechanical forces to the supporting structure. Metal and plastic products are considered universal in this regard.

Metal clamps are suitable for fastening pipes of various types and sizes. Plastic fasteners - only for small-diameter pipes made from polymer materials. To prevent damage to the surface of the hollow pipe, the clamps are equipped with seals made of elastic materials.

The basis for sealing the clamps is profiled rubber having a cellular structure. When working with pipelines that are subject to increased hygienic standards, food grade rubber is chosen as a sealant.

Steel fasteners can provide floating free fixation. They are recommended for use when chimney installation And installation of heating systems. They securely fix the structure and reduce vibration, but do not compress the pipeline when it expands during heating.

It is better to place metal fasteners in areas partially hidden from prying eyes. Plastic clamps practically do not spoil the appearance of the pipeline. They are convenient to use when installing internal communications.

By design

If you focus on the design, then there are several types of pipe clamps.

But still, they can be divided into two types:

- one-piece – one-piece structures;

- detachable - connections from several segments, for assembly of which threaded pairs or special locks are used.

One-piece fasteners include “U”-shaped structures. They have the form of simple arcs, which are fixed to the pipes using nuts.

To install such fasteners, the ends of the strip are moved to the side so that it can be placed freely on the pipe. After this (to increase the pressure of the seal), the ends of the tape are fixed and tightened with a locking or threaded connection.

Another example of permanent fasteners are mounting clips. Clip-shaped holders are used for fixing lightweight polyvinyl chloride or polypropylene pipes small diameter.

Mounting clips are mainly installed to relieve the pipe body from mechanical stress, and therefore they do not require a tight connection of the ends of the strip.

Band clamps have the shape of a split ring, which opens on one side due to the movable connection element. They are made from strips of bendable sheet material. They are fixed to the pipe using special fasteners.

Most often, the basis for the manufacture of such products is a perforated metal or plastic tape equipped with a lock with a worm screw. To install such parts, the toothed track is unrolled in order to be placed on the pipe. Then the end of the strip is inserted into the hook and gradually tightened by rotating the screw.

Clamps with studs are more complex fastening structures. Such elements are produced with a rubberized inner surface. “U”-shaped fasteners and clamps with studs are considered the most reliable. They are used for fixing heavy metal pipelines.

To secure closely spaced pipes, manufacturers offer double clamps. On sale you can even find clamps equipped with grounding elements. Their design includes rods with pointed ends, designed to create reliable electrical contact of the mounted pipe with the ground loops.

By product size

The key parameter when choosing a fastening device is the nominal diameter of the product - “Dn”. It indicates the diameter of the pipe for which the fastening structure is used.

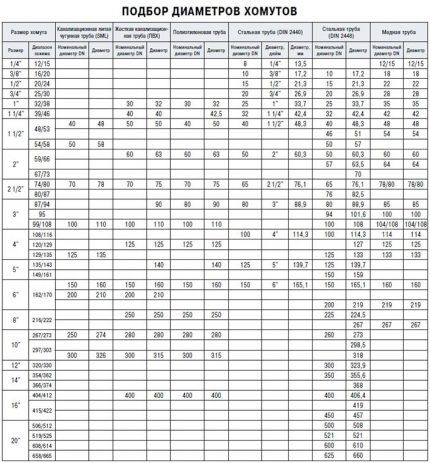

Fastening clamps are produced for pipes of almost any diameter. The range of diameters of commercially available fasteners is from 14 to 540 mm. The table below will help simplify the task of choosing the size of the product.

Metal clamps used for fixing pipelines are produced in accordance with GOST 2413780. Parts made of polymer materials are in accordance with parameters 17679-80. The technical parameters of the holder can most easily be determined by the markings applied to the surface of the product.

For device silent sewer, the article we recommend will introduce you to the design features of which, they produce special types of shock-absorbing clamps. These devices dampen the movement of pipes and prevent the propagation of sound waves.

Features of mortise models

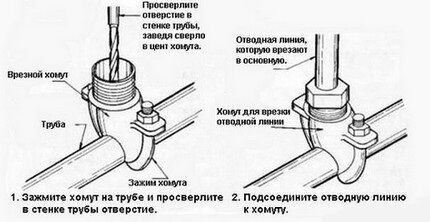

In places where it is intended to create a branching point for the pipeline without using fittings, mortise clamps for the pipe are installed.

Clamps for tapping into the pipe body are installed on a pre-drilled hole.

The built-in threaded pipe allows you to connect an additional section of pipeline in a matter of minutes. A gasket attached to the inside of the clamp body ensures the tightness of the connection.

Options for the mechanical part of the ties

Any model of fastening screw is equipped with a fixation unit. There are models with fastening at one point and those that are fixed in two or more places.

Devices with fastening at one point can be equipped with a pin with a pointed end and threaded threads, or have a hole for mounting self-tapping screws. Fastening of such clamps is carried out using polymer dowels.

Making a clamp with your own hands

In the absence of the opportunity to purchase a production bracket, the mounting device can be made on your own. Let's look at how to correctly make and install a metal clamp on a pipe.

The easiest way to make a crimp band is from a strip of sheet steel. For this purpose, it is best to use sheet metal with a galvanized surface 1 mm thick. To connect the ends of the strip you will also need M6-10 bolts.

Set of tools required for making fasteners:

- hammer;

- vice;

- calipers;

- spanners;

- pliers;

- metal scissors;

- Bulgarian.

To drill the mounting holes, you will also need a drill with a set of drills of the appropriate diameter. To prevent the rubber gasket from moving relative to the metal bracket, you can use construction adhesive.

Using a caliper, measure the diameter of the pipe that needs to be attached.

A strip 4-8 cm wide is cut out of a piece of sheet steel. To correctly calculate the length of the strip, the resulting pipe diameter is multiplied by the number “Pi”, i.e. at 3.14. This will be the length of the product. But in order to be able to make ears for fixation, another 3-4 cm should be added to the length value.

Using metal scissors, the workpiece is cut out, giving the strip the required shape.In the area where the bracket ears are located, 2 holes are drilled.

The number of bolts directly depends on the width of the strip:

- for holders up to 6 cm wide, a pair of fasteners is enough;

- if the width of the bandage is 6-8 cm, it is better to install three bolts.

If the purchased bolts have large heads, the diameter of the holes can be expanded by a couple of millimeters. Ideally, it is better to purchase metal washers for fasteners.

To make a rubber layer, a piece of flat rubber is cut out of a slightly larger size than the one made of steel. It is fixed to a metal bracket by applying a layer of construction adhesive.

With the finished bracket, all that remains is to tie the pipe in the right place, connecting the ears to each other using bolts. The clamp installed on the pipe is attached to the wall.

How to install a clamp on a pipe?

There is nothing difficult about installing a clamp and securely securing the pipe. Even a novice master can perform installation work.

General rules for the location of fasteners

Regardless of whether you have to install a plastic or metal clamp, when positioning the fasteners it is important to observe the distances prescribed by the standards:

- For pipes with a diameter within 20 mm, provided that the temperature of the passing liquid does not exceed 60 ° C, the distance between the clamps should be 80 cm.

- For pipes intended for supplying hot water larger than 20 mm, fasteners are placed at an equidistant distance of 65 cm.

- When fixing pipes D 40 mm intended for transporting cold water, a step of 110 cm is maintained when placing the clamps.

- For hot water pipes D 40 mm, the distance is reduced to 95 cm.

- If you need to install pipes D 110 mm or more, then for “cold” pipelines the distance between the clamps should be about 180 cm, and for “hot” ones - 160 cm.

Additionally, it is recommended to install clamps on the bends of the pipeline and at the installation sites of taps, valves and connecting fittings.

The process of closing a small fistula on a water pipe will be presented in the following photo selection:

Selection of required materials

In order to install the clamp on the pipe you will need a set of tools:

- roulette;

- electric drill;

- building level;

- a simple pencil;

- screwdriver;

- hammer.

To secure the fasteners, you will also need plastic restrictive dowels.

Device installation technology and pipe fastening

The main stages of work on attaching the pipe to the wall by installing clamps:

- Along the entire length of the pipeline, adhering to the above standard distances, markings are applied indicating the locations of fasteners.

- At the designated points, using an electric drill, drill holes for mounting clamps.

- Plastic restrictive dowels are driven into the holes made, using a hammer for this purpose.

- Using a screwdriver, screw the clamps. When tightening the clamps, it is important not to overdo it so as not to disturb the plane of the fastening.

- The main elements are inserted into the clamps, applying slight pushing forces.

- Bolts are pulled through the holes of the lugs and the clamps are tightened by screwing, ensuring a tight fit to the wall.

When drilling holes for installing fasteners, keep in mind that their size must correspond to the diameter of the fastening bolts.

Particular attention should be paid to the angle at which the holes are made and the drilling depth.

If the fasteners are not placed in the same plane, the pipeline will begin to bend over time. This will cause noise “effects” to occur during the passage of liquid. And in places of inflection, the likelihood of accumulation of mud sediment increases.

Conclusions and useful video on the topic

Several useful recommendations from the videos will introduce you to the intricacies of attaching clamps.

Some of the ways to attach a sewer pipe are:

The following video will introduce you to the intricacies of choosing a clamp for fixing a pipe:

Video guide on using a clamp as a repair element:

By choosing a holder wisely and attaching the clamp to the pipe in accordance with technical standards, you can ensure the strength and reliability of fixing long and unstable sections of the pipeline.

If you have ever secured pipes using clamps, share your experience with site visitors. It is possible that you know technological subtleties that are not mentioned in the article. Please write comments in the block below, post photos on the topic and posts with your opinion, and ask questions.

I usually use steel clamps with a rubber gasket. Where I can use a double clamp, I always do just that - it looks very neat, people are happy. With your own hands, if suddenly the circumstances have developed in some interesting way, the clamp is perfectly made from perforated metal tape. You simply cut off the piece you need, grab the pipe and tighten it with a bolt and nut through the perforations on the free tails.Yes, it’s rude and unaesthetic, but the option is quite workable. Just make a rubber gasket out of something. I once urgently closed a fistula that had formed on a pipe with hot water. Water flowed through the pipe from a small crack. Surprisingly, this clamp with an attached rubber band, as it turned out, lasted for more than one year, and no water leaked.