PPR 32 pipe: characteristics of various types and installation methods

For laying communications, they often use not metal pipes, but more modern ones made on the basis of polymers.The characteristics of polypropylene products (PPR) allow them to be used in various fields - agriculture, mechanical engineering, construction. Manufacturers produce pipes of different structures, but at the same time strictly complying with GOST requirements. The PPR 32 pipe is widely used for the construction of utility networks, so it is worth familiarizing yourself with its features.

The content of the article:

PPR pipe categories 32

The base is thermoplastic “Random Polymer”. It has an ideal tandem - resistance to elevated temperatures and better qualities than previous polymer options. This determined the scope of its application.

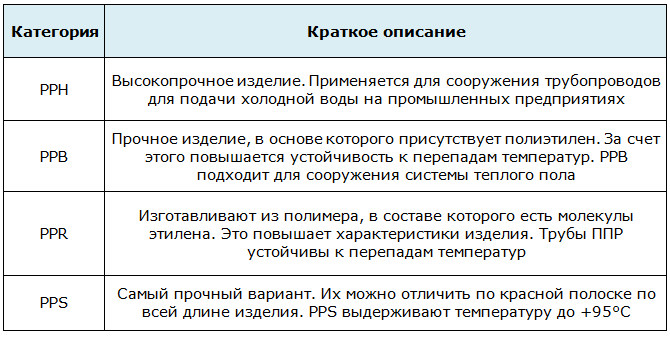

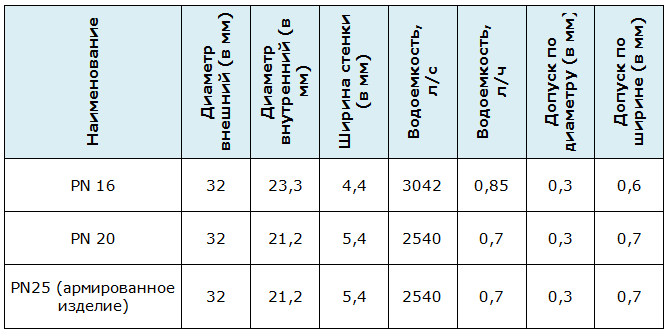

The categories of PP pipes are described in the table.

The PPR 32 pipe is lightweight. Density – 0.91 g/cm³. Due to this, the product is easy to transport to the installation site. There will also be no difficulties connecting the elements of the engineering structure.

PPR 32 is suitable for:

- heating a country house or apartment;

- plumbing with hot or cold water - the products retain their characteristics at temperatures from -5 to +140 °C.

With the help of PPR 32, it is possible to lay the engineering system only inside the building. They are not suitable for laying communications outside a house or apartment.

Other advantages of PPR 32 over metal analogues:

- products do not rust;

- do not collapse when exposed to aggressive environments;

- service life, subject to proper installation and operation, is more than 50 years;

- easy installation - the pipes are connected to each other with polypropylene fittings. They are welded using electric welding, which can be bought on the market;

- · the smooth inner surface does not allow debris, salts, etc. to settle on it.

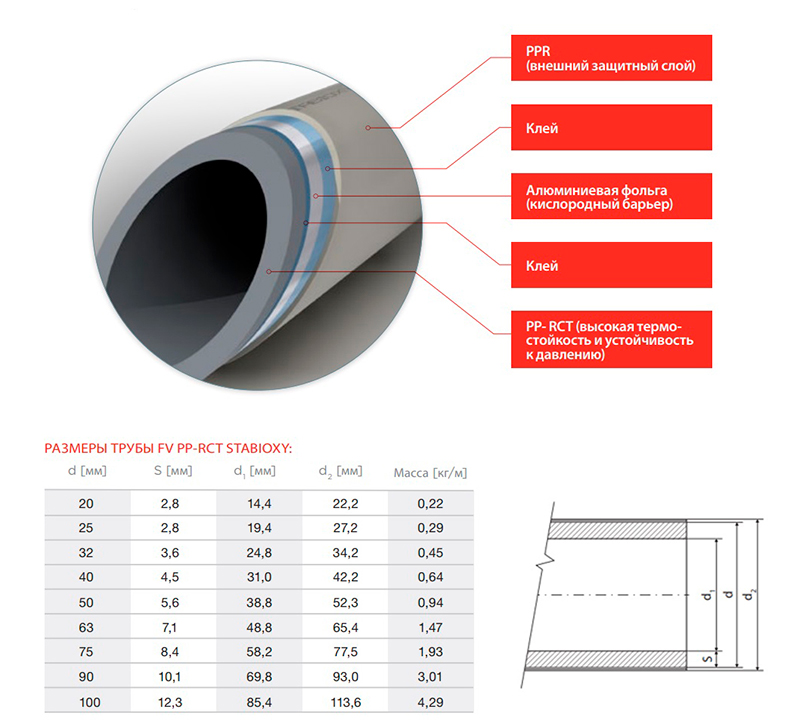

Features of reinforced pipe PPR 32

The PPR 32 reinforced pipe has a layer of aluminum or fiberglass inside, which increases its resistance to thermal expansion. A product reinforced with foil has an anti-diffusion barrier, which eliminates the possibility of oxygen molecules penetrating through its walls.

Types of PPR 32, depending on the reinforcing layer.

Characteristics of PPR 32 pipe

When choosing 32 mm PPR pipes, you need to rely on the standards for them. Indicators of quality products will not deviate from them. Therefore, you should ask the seller for documents and certificates and study them.

What to look for when buying a PPR 32 pipe

To lay water supply in a private or apartment building, you need to purchase PPR of different diameters. But before purchasing, they carry out calculations that will help determine the size of the products, since different sections of the water supply network can supply different amounts of water and under different pressures.

To calculate the diameter, use the formula – D=√((4)-Q-(1000/π∙v)). Under v we take the flow velocity in m/s. The standard Pi number is 3.14.

Technical characteristics that receive special attention:

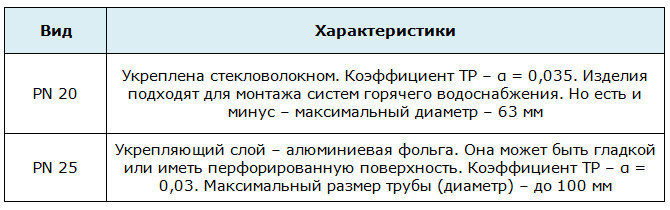

- pressure. For the construction of a heating system for an apartment building, PPR 32 PN25 is suitable, and for a country house - PN20;

- temperature of the working environment. The optimal value is +90 °C.

The surfaces of PPN 32 must be free of signs of destruction. Small longitudinal stripes or humps are not considered defects and do not affect the quality of the product.

It is better to buy pipes from well-known manufacturers and in relevant stores, as otherwise you can buy a Chinese counterfeit.This is fraught with a reduction in service life and the possibility of an emergency (for example, a rupture in a pipeline).

What is needed to install a pipeline made of PPR 32

A person with minimal knowledge in the field of carrying out household technical work can connect polypropylene pipes into one connection. The products are inspected before installation. They must not be damaged or dirty. You need to work with them carefully and keep them away from open flames. The pipeline is installed at positive temperatures - at least +5 degrees.

Materials and tools for work:

- electric welding machine and attachments for it;

- pipe cutting scissors. If there are none, you can use a jigsaw;

- PPR 32;

- fitting;

- gloves;

- protective glasses.

Welding algorithm:

- Select the required nozzle for electric welding. After the device is activated, it is heated to +250-270 °C.

- Using scissors or a jigsaw, cut the pipes into the required lengths. The cut areas are polished.

- Connect the pipe and fitting, mark the maximum insertion depth on them.

- A pipe and fitting are placed on the heated electric welding nozzle. Warm them up.

- Remove the parts from the nozzle. Carefully insert them one into the other until the marks are reached. Wait 30 seconds for the material to harden.

PPR 32 pipes are one of the most popular today, because they are suitable for the construction of utilities of any type. Working with them is not difficult. But as a result, you can get a high-quality heating system or plumbing that will last more than 50 years without changing its characteristics. Price per meter – from 30 rubles.

What do you think, are metal pipelines better or polypropylene? Write in the comments. Save the article to bookmarks and share it on social networks.

Secrets of installing polypropylene pipes.Master class for beginners in video.