What is argon welding: how to use it correctly, step-by-step instructions

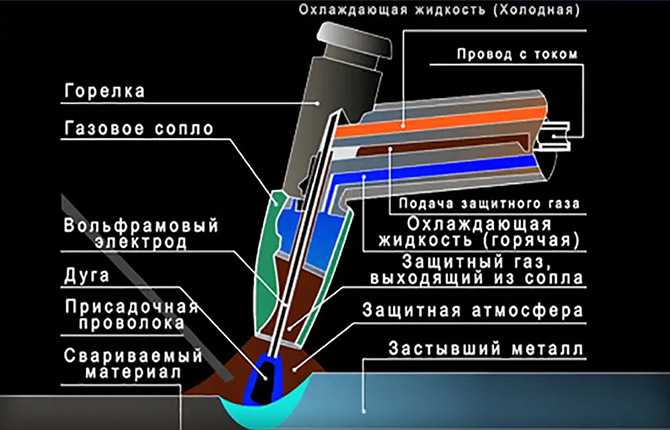

Argon welding is one of the types of electric arc method of joining metals.An arc is ignited in a sphere of inactive gas using a tungsten electrode. At the same time, the edges of the welded parts melt, reliably joining together into one whole.

The content of the article:

Argon welding - features and description

A characteristic feature of argon welding can be considered the successful combination of electric and gas welding principles. This welding technique produces excellent quality welds. They are carefully sanded and at the end of the entire work cycle, the joints are absolutely invisible.

The main factor in the process is the electric arc. Here the transition of electrical energy into thermal energy occurs. A high thermal threshold melts the metal at the welding point. If you move the arc smoothly, you get fusion of the material and a reliable connection of the workpieces. By moving the electrode, the parameters of the weld pool are adjusted, the welding speed, the degree of penetration, the quality and width of the seam are adjusted.

To fill the gaps and weld a high metal bead onto the seam, filler wire is used. It must be identical in composition to the material being welded. The filler wire is fed to the melting point manually.

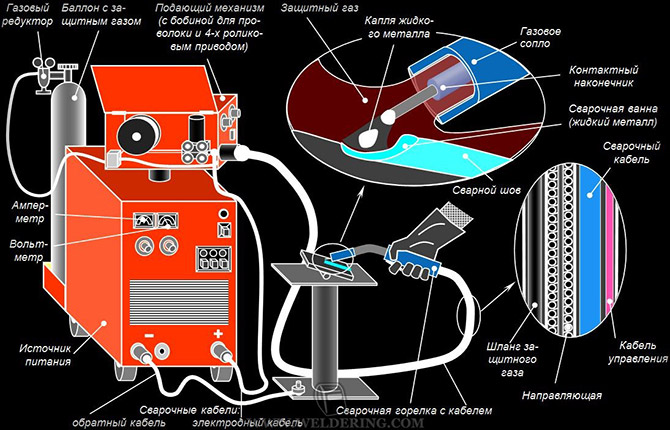

The supply current source is an inverter-type unit with controls, a neutral gas supply system, and connectors where the burner is connected. The current can vary, be either constant or alternating.

When an argon welding unit is operating, inert argon gas is supplied through the tool nozzle into the arc zone. It “displaces” atmospheric air, including oxygen and nitrogen, from the weld pool. The metal seams are thus reliably protected during welding. The base of the arc, a non-consumable tungsten electrode, is also protected. If welding is carried out without inert gas, tungsten is exposed to the aggressive influence of oxygen and is destroyed.

Atmospheric air negatively affects the quality of the welding process. Inert gas is used to protect the fusion zone from atmospheric oxygen. In common practice this is argon. Helium can be used for this purpose, but its cost is much higher. The low price of argon is explained by the fact that it is just a by-product of the industrial air separation process into oxygen and nitrogen.

Advantages of argon arc welding:

- Aesthetic, high-strength seam.

- No fluxes or electrode coatings are required.

- Work with parts of any size.

- Possibility of welding metal onto damaged parts of parts to restore them.

- Connecting difficult-to-weld metals (titanium, cast iron, aluminum and others).

- Minimum emitted aerosols compared to other types of welding.

- The edge of the metal cut “in argon” has an ideal geometry; oxide and nitride films do not form on it.

- The argon method allows you to connect thin layers of metal and perform special welding operations.

The disadvantages include the fact that argon welding of metal is slower than with other welding machines and methods.

Working with argon poses a danger to human health.Inhaled argon gas causes dizziness, can lead to nausea, vomiting, loss of consciousness and even death. Those working with argon welding often experience headaches, ringing in the ears, fatigue, disturbances in the digestive tract, and breathing problems.

A welder runs the risk of developing aluminosis, an irreversible pulmonary pathology, as he is exposed to the negative effects of ozone, radioactivity, and nitrogen oxides.

Classification of argon welding

Argon welding technology is classified according to individual functional principles:

- Manual method. Manipulations of the torch, arc torch, and additive are performed manually by a welder. His experience and qualifications set the pace of the process and the parameters of the welds.

- Semi-automatic. The equipment has a function for feeding filler wire. The installation is equipped with a wire feeding mechanism. The welder operates only with an argon torch, leaving one hand free. It can be used to hold or unfold workpieces. The method is more productive than manual, but the qualifications of the welder are very important.

- Auto. Wire feeding and movement of the carriage with the torch occurs automatically, without the participation of a worker. The advantage is smooth, high-quality welds. The operator’s functions are to control and correctly set the parameters - the depth of the required penetration, the optimal speed of movement of the carriage, etc.

In addition, argon welding is differentiated by the actual process - whether filler wire is used or not.

Without an additive, you can weld thin metal (up to 2 mm), with tight pressure - there should be no gaps along the seam. Then the edges are melted with an electrode and this metal is enough to join the workpieces.The result is a sealed, thin, smooth, mirror-like seam without “scales”.

It takes longer to cook with filler wire. The type of weld is “scaly”, and the number of layers of scales directly depends on the rhythm of the additive supply into the weld pool. Gaps and spaces between parts up to 5 mm wide are melted with high quality, and convexities are fused for grooves. The filler method is used for argon welding of metals with a thickness of 3 mm.

Not long ago, another innovative argon arc welding technology appeared - robotic. Its peculiarity is that welding of parts on conveyors is performed by robotic complexes. The method is characterized by high productivity and low cost of work.

The disadvantage is the significant cost of unique equipment, the urgent need to attract highly qualified specialists for maintenance, software support, and fine-tuning of robot components. The technology is designed for large production volumes.

Argon welding - what tools and equipment you need

Equipment and accessories for argon arc welding are divided into 3 groups.

The first includes special devices that perform one specific operation. Argon welding, carried out by such devices, is used in large enterprises of large-scale continuous production.

Second – specialized equipment that is configured for operations with a narrow range of parts of a specific category.

Third – universal machines, used for several types of operations and materials. This is the most popular group of commercially produced devices.They are widely used not only for industrial purposes, but are in great demand among handicraft and “garage” craftsmen.

Set of equipment for universal argon welding:

- workwear, safety footwear, personal protective equipment;

- unit for performing work with a non-consumable electrode;

- tungsten non-consumable electrodes;

- filler wire;

- high pressure hoses;

- gas cylinder;

- gas reducer;

- auxiliary tool.

In a gas cylinder, in compressed form, there is gas - argon. Cylinders are used for various gases. In order not to confuse identical containers with different contents, cylinders are marked. So raw argon is pumped into a black cylinder with a white inscription and a white stripe. Technical argon - also in a black cylinder, but the inscription is blue, the stripe is blue. Pure argon is distinguished by a gray cylinder with a green inscription and stripe. Other special technical information is also stamped on the cylinders.

Each reducer is designed for its own gas. The color of the reducer must match the color of the gas cylinder. In a cheap option, you can use a “black” carbon dioxide reducer. But most often a reducer with a rotameter is installed under argon.

High pressure oxygen hoses are used for argon due to their quality and reliability. The internal diameter varies from 9 to 18 mm. So choosing the right one will not be difficult.

The current source for argon welding is selected according to the goals and tasks that need to be performed during the work.

Tungsten electrodes are designed to ignite and maintain the arc. They have appropriate markings characterizing their properties and the presence of special impurities.

Auxiliary materials are needed to prepare metal for welding, for example, a grinder, various metal brushes.

Safety Compliance

Argon, like any other welding method, requires strict adherence to safety regulations. They are mostly simple, but their implementation allows you to save not only health, but also life.

Work must be organized in special rooms or cubicles. Where it is not possible to implement these conditions, the place for argon welding work is fenced off with screens. They are panels made of plywood, painted with a fire-resistant composition, which also includes zinc oxide, which absorbs ultraviolet rays. The height of such a fence cannot be less than 2 m.

Argon welding equipment is installed on a level area in compliance with technological dimensions. The welder's workplace must be equipped with exhaust and supply ventilation. Exhaust panels are very effective. They are positioned horizontally or at an angle so that contaminated air from the arc is pumped down or away from the welder. This prevents harmful substances from entering the worker’s respiratory tract.

What you need to do before you start:

- Inspect and make sure that the welder’s special clothing, shoes, and protective equipment are in good condition, clean, and not soaked in oil or other flammable substances.

- When putting on overalls, fasten all the buttons, tie the ribbons, and lace up the shoes.

- The jacket and trousers must be worn untucked, the pockets must be closed with flaps, and the hair must be tucked under the headdress.

- Check the workplace, lighting, hood.

- Remove unnecessary workpieces, unnecessary items, and flammable materials.

- Inspect the equipment.It must be reliably grounded, the high voltage contacts are protected and closed, and the integrity of the wires is not compromised.

- Make sure that measuring and signaling devices and equipment locking devices are working.

- Do not begin work until the identified deficiencies are completely eliminated.

How to properly use argon welding step by step instructions

Before welding, the workpiece must be thoroughly cleaned of dirt, machine oil, and grease deposits. This can be done with any solvent. When the thickness of the welded parts is over 4 mm, edge cutting is necessary, and argon welding is performed only butt-to-butt.

To destroy oxide films, the joint is treated with metal brushes. A connection with complex geometry is cleaned with an angle grinder.

To remove moisture, the workpieces should be heated to 150 degrees. To avoid burn-through, copper or steel plates are placed under thin metal to remove heat.

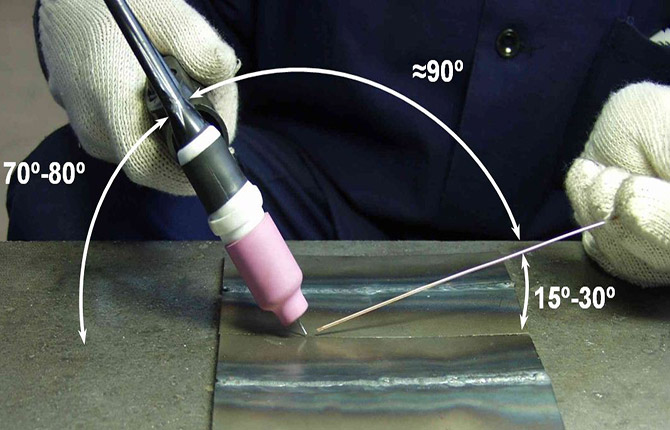

The additive moves exclusively in front of the burner, along the weld being welded.

A short time (5-7 seconds) before igniting the arc, the supply of inert gas is turned on. After finishing welding, you again need to wait the same time before turning off the gas.

Sequence of actions for working with argon arc welding:

- Turn on the equipment.

- Connect the ground wire to the welding table or workpiece.

- Open the valve on the gas cylinder.

- Bring the argon torch closer to the part to be welded so that the distance to the electrode is 3-5 mm.

- Put on a protective mask and turn on the power supply.

- Hold the resulting welding arc at the initial edge of the joint until a puddle of molten metal forms.

- Using circular, smooth manipulations, achieve melting of the edges of the sides.

- Maintain an angle of 45 degrees between the burner and the surface.

- Slowly and carefully move the torch with the needle forward, feeding the filler wire into the torch.

- At the end of the weld, reduce the current to fill the crater.

Argon welding is a profitable innovative method for restoring products. The cost of welding and restoration work is significantly lower than the production of a new part. A refurbished product can last for a very long time.

Have you ever used argon welding yourself? Tell us about the characteristics that will help you acquire skills faster. Leave your comment, share the article on social networks, add it to bookmarks.

How to cook with argon welding outdoors in windy weather?

You won’t be able to weld like in a workshop - the wind blows away the shielding gas and leaves the weld pool open to external influences. Protect the welding area with a sheet of iron. If there is nothing suitable at hand, block the wind with yourself by standing on the side from which it is blowing.

What to do if the weld pool bubbles a lot?

Adjust the argon supply to the reducer. There is either too little gas (carbon escapes from the metal) or too much.

How to sharpen a tungsten electrode correctly?

Sharpen the rod on a rotating diamond wheel. It will last longer than a regular sander. Place the electrode with the tip facing away from you on the end of the rotating circle. Achieve a sharpening angle of 20-30 degrees. For welding at currents of 200-300 A, a sharpening of 60 degrees is required.It is more convenient to weld thin metal 1-1.5 mm with the tip, like a needle - the sharpening angle is approximately 10 degrees.