Shower hoses - design features, rules for selection and operation

Over the entire period of operation, shower hoses pump more than one ton of water through themselves.Accordingly, they are subjected to significant loads, and subsequently begin to leak and tear. The time is coming to replace it. But in the store, the buyer is greeted with products of different lengths, which have different braids. Plus, you always come across hoses with different nuts. Therefore, you need to deal with them first.

The content of the article:

What you need to pay attention to when purchasing shower hoses

Purely structurally, a shower hose is a product consisting of three elements:

- a tube;

- braid, which may not exist;

- two threaded nuts - one attaches the hose to the mixer, the second to the shower head.

The tube can be made of plastic, rubber or silicone. The cheapest is the first option, which has little durability. If the shower hose is sold braided, then it is not difficult to determine which tube is laid in it. You just need to look inside. If it is white, then it is plastic. The second option is to determine the material by stretching the hose. Plastic will not stretch, rubber will change the length significantly.

You can buy transparent hoses without braid in the store. These models are even cheaper. Their appearance is immediately attractive, because through the walls of the tube you can clearly see how the water flows. But over time, transparency fades away. The reason is the questionable purity of the water that flows from the water supply. The problem can be solved by installing a flow filter in the water supply system.But this increases the cost of the shower hose.

The second position is braid. You need to buy just such a hose, because the braid serves to protect the tube from mechanical stress, as well as from the negative influence of moisture and temperature.

Material used for this part of the hose:

- metal;

- plastic;

- silicone

The third position is the connecting nuts. The one that has a flat shape is intended for attachment to the mixer. The conical one connects to the shower head. The recommendation here is simple - the thicker the nuts, the longer they will last.

Which hose is better - plastic, metal or silicone?

It is the material from which the braid is made that determines the functional qualities. The stronger, the more expensive.

Metal braid

This is a common option and is therefore considered a classic. It is usually made of stainless steel. But on the market you can find metal shower hoses with braided copper alloys. Models are much more expensive than steel ones.

The shape of the braid is spiral, hence the quality of the product:

- pleasant appearance: chrome, gold, bronze;

- increased flexibility;

- good protection of the tube from kinks and kinks.

There are also disadvantages:

- The braid unwinds over time, which causes damage to the tube:

- service life is short - 5 years;

- dirt and limescale deposits often form on the metal surface, which spoils the appearance.

Plastic braid

Plastic is inferior to metal in many characteristics. But in the case of shower hoses, this is a good option, and it’s also cheap. It easily tolerates high temperatures - up to +80 ℃. It has high flexibility, is not subject to corrosion, and the surface is smooth.Plus – a wide color palette, which makes it possible to choose a product to match the interior of the bathroom.

There are also disadvantages. The largest one begins to crack over time. Therefore, today manufacturers offer a combined, so-called reinforced version. This is a plastic braid with a metal wire inside. Such models have high strength and bendability. Hence, long-term operation and a reduction in the occurrence of cracks.

Silicone braid

These shower products do not use pure silicone. The braid is metal, but covered with a silicone layer. It improves the properties of the product, increasing its service life. But the price is higher. The silicone shower hose cannot scratch the bathtub.

Main selection criteria

Shower hoses are widely available in stores, so it’s difficult to choose what you need right away. And if someone’s first selection criterion is appearance, then it can be deceptive. Therefore, it is recommended to pay attention to other indicators.

Manufacturer

The clear leaders in this area are European companies. German models are of high quality, but their competitors have their own advantages.

The Chinese offer cheap options that cannot stand up to competition. But among them there are manufacturers offering good quality products.

Here is a list of some companies that produce high quality shower hoses:

- Grohe – a German company offering plumbing fixtures that can withstand temperatures up to +70 ℃, pressure up to 5 bar, loads up to 50 kg. The flare nut design contains a bearing that prevents the hose from twisting. This system is called Twist-Free.The surfaces are coated with a special compound that protects them from possible scratches and other minor troubles. Just wipe them with a dry cloth, and the hose will be like new again.

- Hansgrohe - another well-known representative of Germany who produces sanitary ware. Offers a large selection of models: sizes, colors, materials, prices. The most expensive products are guaranteed for 5 years. All offered models are coated with an antibacterial composition.

- Aquanet is a Russian manufacturer. Offers a serious selection, where the price is widely scattered.

- Ravak is a company from the Czech Republic. The quality is practically not inferior to the Germans, but offers normal, not inflated prices.

- Zegor is a Chinese manufacturer that you can trust. Offers a full range, low prices.

Material of manufacture

If we talk about the best models, then these are a rubber tube, silicone braid, and brass nuts. They are not cheap, so you should pay attention to metal ones.

Hose length

On the market this parameter is presented in several positions: 1.25, 1.5, 1.75, 2.0 m. The second is considered standard - it is mainly produced by manufacturers. The optimal length allows you to shower in any part of the bath. In this case, the hose will not interfere with free movement and will not get tangled underfoot.

The first position is installed in hygienic showers or when installing a shower panel. The last two are used only in one case - if the shower panel is high. It is difficult to find them on the market, but you can find them.

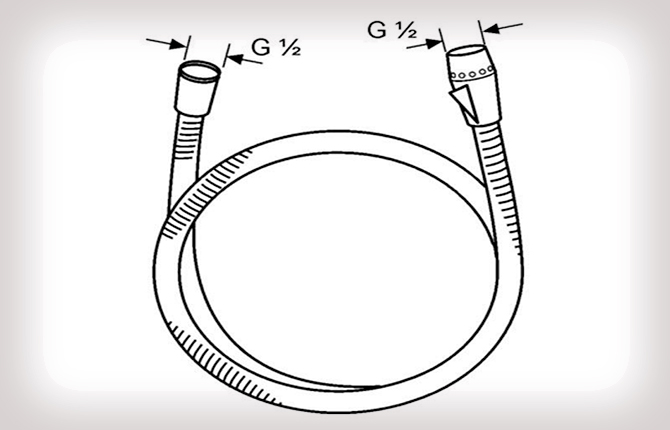

Besides the length, there is one important parameter that you need to pay attention to. This is the diameter of the shower hose. Or rather, the diameter of its connecting nuts. There are two positions here: ½ and ⅜ inches.When choosing, you need to accurately determine whether the diameter matches the same size on the mixer and on the shower head. Therefore, it is recommended to take an old copy with you to the store and make a comparison on the spot.

Equipment

Today, almost all manufacturers equip shower hoses with a system called anti-twist protection. This is a cone nut in which an element is mounted that performs the functions of a bearing.

The nut is divided into two parts. One is attached to the shower head and is stationary, the second is connected to the braid. Both parts rotate freely relative to each other. Therefore, when the watering can rotates in your hands, the hose remains motionless relative to its axis.

Visual inspection of the product

Manufacturers offer sanitary products in different packaging. If it is a box, then you need to open it and inspect the model itself.

What you need to pay attention to:

- If this is a model with a plastic braid, then the color of the coating should be uniform. Heterogeneity is a sign of poor quality, reducing service life.

- If this is a metal option, then the braid should not have burrs, areas with metal corrosion, dents, tears or other defects.

- You should not buy devices with plastic nuts.

- The package should include two sealing collars.

- The packaging must be designed in accordance with the standards: manufacturer’s name, GOST, etc.

- Check with the seller whether the surface is treated with antibacterial and antifungal protection.

If the product is packaged in a transparent bag, then you need to agree with the seller about inspection. And if he doesn’t like something, he must accept the defective sample back without complaint.

Further maintenance and repairs

Installing a hose in the shower is easy.If you purchased the model together with a watering can, then you just need to screw the product to the mixer by hand. You don't need any tools for this. There is also no point in pressing the nuts too hard, because there are seals inside that will create an airtight joint.

If it is necessary to carry out a replacement, then before replacing the shower hose with a new one, you need to select it correctly according to the parameters and points indicated above. Next in order:

- It is necessary to unscrew the connecting nut with which the device is attached to the mixer. This is also done manually. If you can't unscrew it by hand, you can use an adjustable wrench.

- The watering can is unscrewed in the same way. It is then screwed onto the new hose.

- The latter is screwed to the mixer.

Maintenance is even easier.

Three points must be taken into account:

- hang the hose on the holder at all times - do not twist it around the faucet or lay it on the floor of the bathtub or shower tray;

- It is better not to pass water above +70 ℃ through it - it will withstand temperatures even higher, but its service life will definitely decrease;

- You only need to clean the hose with a soft cloth, you can use a sponge. No brushes or chemical detergents.

If the braid is torn, there is no point in repairing it - it is simply impossible. Will have to replace with a new one. Situations often occur when the inner tube ruptures, causing the hose to begin to leak heavily. If the break is near the end, then it can be removed.

This is done like this:

- the sealing collar is removed from inside the connecting nut;

- the nut itself moves in the opposite direction, displacing the braid;

- the tube remains visible, its end placed on a brass muff;

- there is a break point or crack;

- scissors are used to cut off the damaged area from which the coupling is removed;

- the latter is inserted onto the cut end of the tube;

- the nut is put on the end of the tube;

- the cuff is inserted.

This type of repair of a shower hose can be done once, or maximum twice, because the length decreases with each cut.

And one more point regarding the topic of how to fix a shower hose with your own hands. Before inserting the brass coupling into the tube, the latter must be heated by immersing it in hot water. The plastic will soften and expand freely. This makes it more convenient to insert the narrow part of the coupling into the tube. As the plastic cools, it will tightly press itself around the metal pipe, which will ensure the tightness of the joint.

Shower hose - a plumbing element, without which it is inconvenient to wash today. Therefore, before choosing it, you need to know exactly what to look for. There are few parameters, some of them are indicated in the product passport, which you can always familiarize yourself with.

How to choose a shower hose: video.

It would be interesting to hear from our readers who had experience purchasing a shower hose and what parameters they used to choose it. If you liked the article, spread it on social networks, and others will learn about the rules for choosing a shower hose.

Go to the store with your old hose. You can't go wrong with your choice.

If the nuts do not fit the size of the connecting pipe on the mixer, then the solution is to buy a special adapter. It has one end with an internal thread, the other with an external thread. The nut from the hose is screwed onto the latter.