The principle of operation of the Kholmov boiler - the subtleties of operation

The Kholmov boiler is a long-burning, solid fuel shaft-type heating boiler.The peculiarity of the device is that it has 2 combustion chambers. In the first, the fuel smolders, in the second, the afterburning reaction of gases that are released during thermal exposure of the raw material develops. The Kholmov boiler operates on any solid fuel. They produce models with a power of 10,12, 25 kW. Provided the chamber is loaded with fuel at 100%, the duration of heating the premises will be within 12-16 hours.

The content of the article:

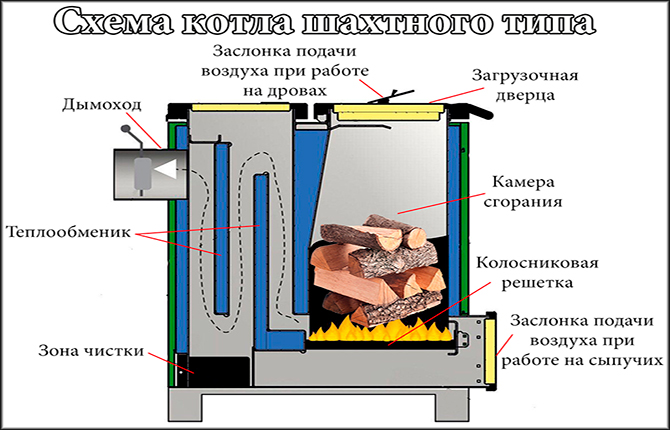

Boiler design

The design of the Kholmov solid fuel boiler is simple when compared with other heating units. It consists of the following parts:

- body (made of metal, can withstand elevated temperatures);

- fuel mine. The user loads any type of solid fuel into it, be it pellets or ordinary firewood;

- chamber with heat exchanger;

- doors;

- grate;

- ash pan (residues after combustion of solid fuel are poured here);

- expansion compensators;

- pipe for supply to the chimney;

- several inputs and outputs for drainage, supply and return, as well as installation of additional devices, such as a safety valve or safety group;

- thermostat.

Fuel is loaded into the Kholmov boiler shaft from above. Combustion takes place on grates at the bottom of the structure. As the wood burns or pellets go down. This ensures continuity of the process and, accordingly, heating.

The top filling is also a plus of Kholmov’s boilers.It is possible, if necessary, to add more solid fuel without waiting for the entire mass in the chamber to burn out.

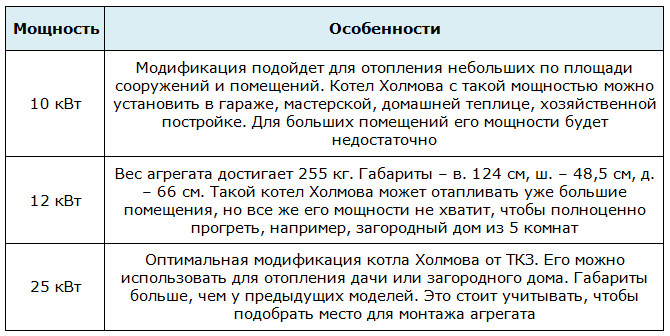

Power differences

Manufacturers have launched the production of three types of Kholmov boilers, which differ in power.

Volatile and non-volatile: what is the difference

The Kholmov boiler can be either volatile or non-volatile. In the first case, the uninterrupted operation of the unit depends on electricity. There are three additional elements in the design of a volatile boiler:

- smoke exhauster (aka fan);

- controller;

- thermostat.

All of them are necessary to ensure safety during operation of the unit.

Non-volatile models are more in demand among consumers, since they do not depend on electricity. The operation of the device is controlled by a built-in thermostat (usually RT3 type). It is mounted on the front wall and connected to the blower door using a chain.

Safety in design

A solid fuel boiler has one weak point - when it gets very hot during fuel combustion, its body part can expand. This is fraught with divergence of welds and the creation of an emergency situation. To exclude the possibility of this, manufacturers included compensators in the design of the Kholmov boiler. They are localized around the perimeter of the heating device. There are also compensators between the chambers.

The dividing walls are located at a distance of 24 cm from each other. There are no compensators in the heat exchanger, since its dimensions allow it to easily maintain its original shape even when the unit is severely overheated.

Operating principle

The operating principle of the Kholmov boiler is based on the combustion of loaded fuel and afterburning of gases.It is worth noting that the amount of gases will be greater, the less oxygen entering the system. As a result of the fact that 2 principles are involved in the operation of the boiler, maximum heat generation is achieved.

Combustion process

The Kholmov long-burning boiler begins operation by loading fuel into the shaft. Part of it will burn and smolder due to the supply of oxygen. The result is a lot of smoke and tar. As the smoke passes through the fuel material, it will enrich it. It is also worth noting that during the smoldering process they can release active substances that burn longer and produce more heat. This ensures “long burning”.

At one refueling, the heating unit can continuously generate heat for 12-16 hours. Combustion occurs as follows:

- the bottom layer of loaded fuel is ignited;

- smoke accumulates in the upper part of the chamber;

- after burning the bottom layer, the fire spreads to the top;

- smoke accumulates in the lower chamber, passes through combustion products (coals), thereby becoming enriched. The result is pyrogas.

Upper and lower chamber

The chambers are separated from each other by a steel partition, which provides a small gap. Through it, the fire spreads from the lower part (compartment for enriching combustion products) to the upper part (convection chamber). As a result, efficiency increases significantly.

During the combustion process, the temperature in the lower sector of the upper chamber reaches 800 degrees Celsius. Most of the heat penetrates into the water jacket. The rest of the heat is transferred outside through the pipes to heat the room.

The following can be used as fuel in the Kholmov boiler:

- sawdust;

- coals;

- briquettes;

- firewood and so on.

Experts do not recommend using coal for ignition.This is a natural product, the combustion process of which will not release pyrogens.

Advantages and disadvantages

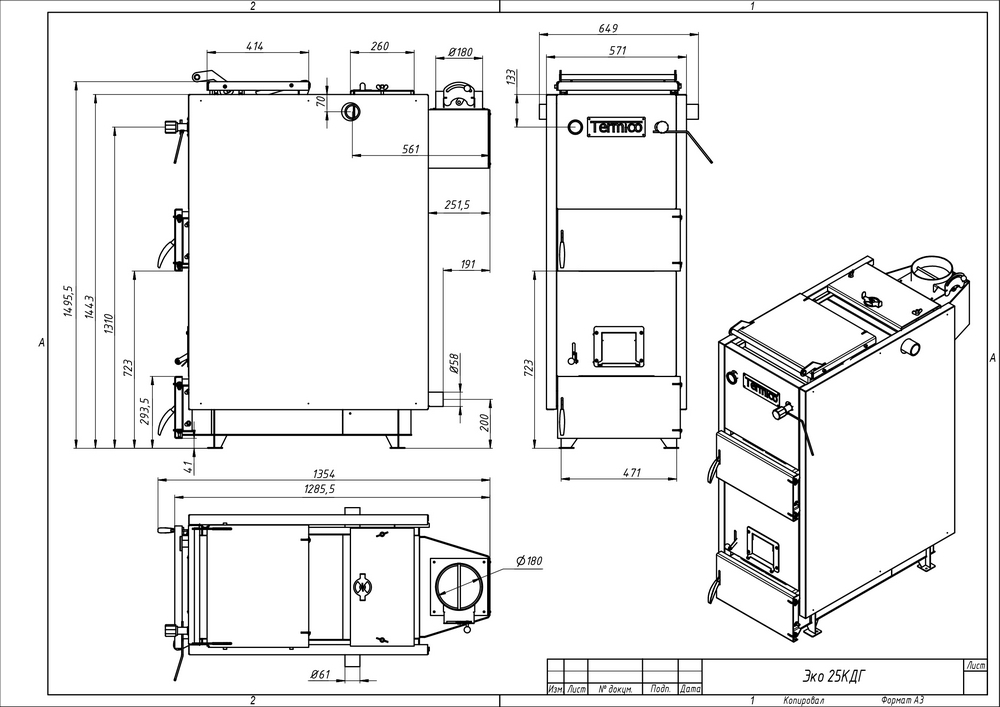

The heating unit has both advantages and disadvantages. You should familiarize yourself with them before making a purchase or, using the drawings of the Kholmov boiler, constructing it yourself.

All benefits

The advantages of Kholmov boilers include the following:

- ability to operate on any type of solid fuel;

- high efficiency. The range includes 3 boiler options with different capacities. Therefore, the user has the opportunity to choose exactly what he needs;

- work autonomy. Non-volatile models can work without human intervention for up to 16 hours on one tab;

- safety. The design eliminates the possibility of carbon monoxide leakage;

- optimal dimensions that allow you to install the heating unit even in a small room.

The only drawback

During the use of the Kholmov boiler, soot and tar accumulate on the walls of its chambers and compartments. And it is not always possible to completely clean them. To minimize the possibility of soot accumulation, it is recommended to equip the heating unit with a smoke exhauster.

The Kholmov boiler is used in industrial buildings and private households. It copes well with heating country houses and cottages. Among its advantages are high efficiency, fuel economy and the ability to burn for a long time on one load. Manufacturers produce models of 10, 12, 25 kW. Therefore, you can buy exactly the device that will meet all the stated requirements.

Do you think the Kholmov boiler is really that economical? Write in the comments.Save the article to bookmarks and share it on social networks.

An honest review of the operation of the Kholmov boiler.

Is it worth buying a Kholmov boiler?

I had a Kholmov boiler in my dacha. And I'm not at all happy with it. Yes, it doesn't smoke, that's a fact. But soot and burning on the walls is still a pleasure. Yes, and he heated my 4-room house weakly (12 kW). I don't recommend it. Maybe it’s suitable for a garage, but for a home... well, I don’t know.