Cheap and beautiful fence for the home - budget and original fencing methods

Having bought a country plot and started planning the construction of a house, many try to save money on the construction of non-essential structures. For various reasons, a fence is included in this category. But, as practice shows, there are few cheapest fence options. And not all of them meet the requirements of land owners.

The content of the article:

What to make an inexpensive fence from

The most budget-friendly option for a fence for a private home is one that is constructed from building materials left over after the construction of the main buildings:

- Houses;

- baths;

- garage and others.

Fortunately, there is always a lot of such goodness left. Plus - erecting the structure with your own hands will ensure a low-cost operation.

But more often, developers are looking for other ways - not the easiest ones. Therefore, they decide to build a fence for their dacha from new building materials purchased on the market. Therefore, the question of which fence will be cheaper arises in their minds as soon as they visit this market.

It's all about the wide variety of materials that suppliers and manufacturers offer today. Quality, service life, price and other nuances are different. Hence the problem of choice.

Why do you need a fence?

First you need to understand for yourself why you need a fence at the dacha. Previously, it performed only protective functions, plus it indicated the boundaries of the site. Today, this structure is increasingly treated as a design element.Accordingly, stylish appearance is not the last place when choosing a building material.

But, as practice shows, making a cheap fence is not always possible if the external beauty of the fence is a priority.

What to make fence posts from

If we talk about the “cheap fence” category, then for the posts, as for the elements that perform the functions of load-bearing structures, it is necessary to select used materials. It could be:

- metal profile. More often, pipes of different sections, sizes, and shapes are used;

- lumber - logs or beams;

- concrete products.

But used metal and reinforced concrete products can be the same in price as new wooden products. Therefore, it is worth thinking about whether, perhaps, preference should be given to the latter.

We recommend reading the article “Do-it-yourself fence from corrugated sheets: step-by-step instructions on building a fence».

Wooden pillars

Some types of wood, namely pine and spruce, are easy to process and are inexpensive, which is why they are used as fence posts. They are treated with protective compounds. And the lower part, which is laid in the ground, is covered with hot bitumen and additionally covered with roofing felt or other rolled waterproofing material.

The service life of wooden poles is 15-45 years. They must be periodically serviced so as not to reduce the operating time. This usually involves painting or varnishing, coating with protective compounds and other operations.

Metal

Today, the most commonly used building material for poles is profile pipe made of black or galvanized steel. The second option is preferable because the service life of such products is almost three times longer. But the price also exceeds the first option.Another disadvantage of galvanizing is that welding such products manually is hazardous to health.

As with wood, black steel products are coated with protective compounds, especially for parts that are buried in the ground. Protective operations are also carried out when the pillars are concreted. It is also better to waterproof the bottom of a galvanized pipe. The top can be left in its original form - it has a presentable appearance.

Pipe supports are used in various fencing structures: covered with corrugated sheets, with chain-link mesh, and others. Of all the options offered, this is the most versatile.

Brick

This is not to say that brick fence posts are a cheap option. Their construction requires a lot of building materials:

- brick;

- cement;

- sand;

- crushed stone;

- net.

At the same time, not everyone can lift brick supports with their own hands. That is, you will have to fork out for the services of craftsmen, which increases costs.

In this regard, all other options are simpler. For example, a pipe or timber. Wells are simply dug under them, where the pillars are installed, backfilled with excavated soil.

Reinforced concrete

There are two options here:

- finished reinforced concrete products;

- poured independently in the form of a monolithic structure.

With the help of the former, it is faster to build a fence, because they are delivered to the construction site in finished form. You just need to install the supports manually.

The second option is more difficult in terms of carrying out all the work. To do this you will have to:

- prepare the formwork;

- manufacture and install a reinforcement cage into it;

- prepare concrete solution;

- pour the latter into the formwork;

- wait for the poured mixture to gain its original strength, which may take 10-30 days.

And after this, the finished supports can be installed to build the fence.

Regardless of this, both options allow you to create a structure that will last for decades. But regarding the price, this is also not a cheap option.

Materials for cheap fences

To build a fence for a summer house that would not make a big dent in the family budget, you need to choose the right building material to fill the space between the supporting posts. A wide range of these materials makes it possible to make the right choice. But before that, it’s worth studying the advantages and disadvantages of each option.

Metal corrugated sheet

This is one of the popular materials for constructing fences.

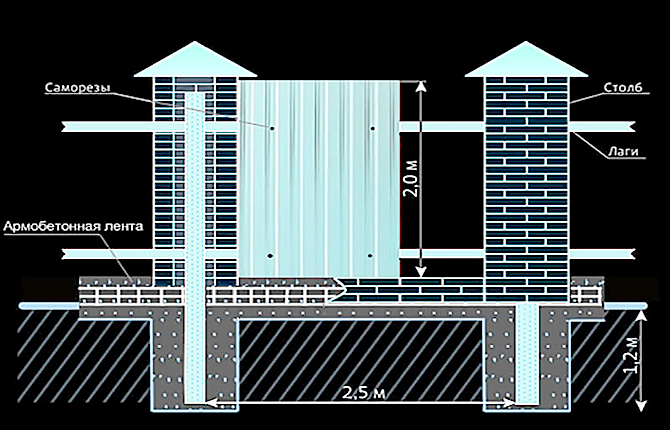

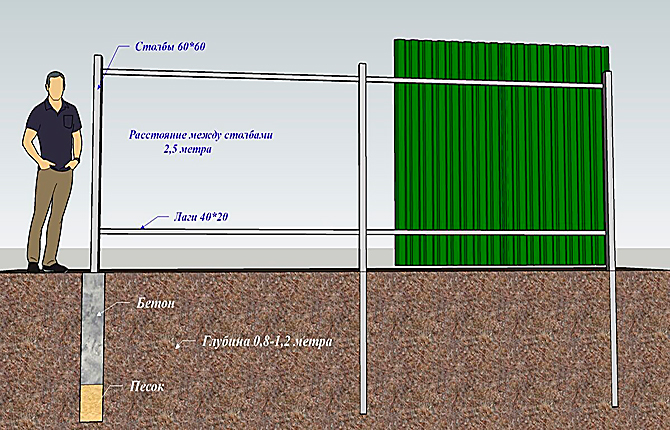

It is easy to erect a fence from corrugated sheets, for which pillars from a profile pipe are used, to which horizontal rows of logs are attached. The number of the latter can be 2 or 3 rows depending on the height of the fence. Above 1.7 m lag there should be three rows.

Sheet fastening options:

- roofing screws with a hex head;

- anti-vandal screws;

- aluminum or stainless steel rivets;

- a combination of several options.

It is impossible to say that this is a simple fence. The design itself is simple. Difficulties may arise when installing it yourself. Especially if the installation is carried out by one person.

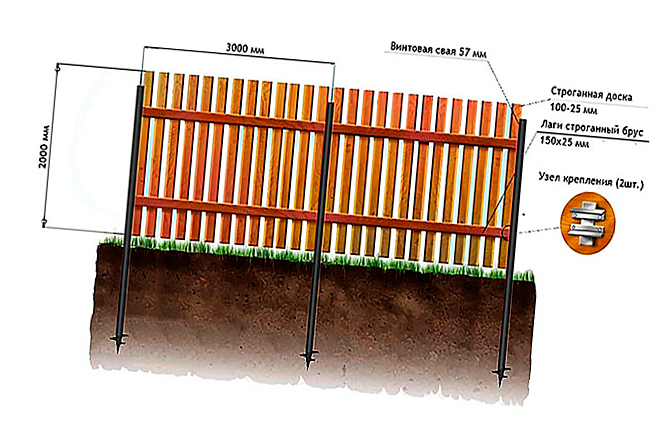

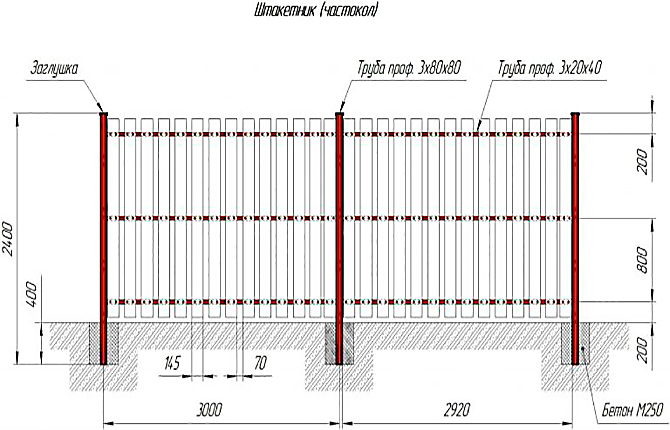

From a wooden picket fence

This material has been used in the construction of fences for a long time.

It’s not difficult to make such a fence with your own hands so that it’s cheap and beautiful. There are many design solutions for fencing structures made of picket fences. The simplest and cheapest design is vertically installed planks with a gap between them. You can do it without gaps, you can do it with them, but install the planks in two rows on opposite sides of the lag.

Purely structurally, a picket fence is:

- wooden poles dug into the ground;

- they are tied with slats that serve as logs (2-3 rows);

- picket fence strips are stuffed onto the logs or secured with self-tapping screws - with gaps or tightly.

The fence is being processed antiseptic and fire retardant, coated with a protective composition: paint, varnish of different shades.There is a technology for burning wood that extends its service life.

Unedged board

This is another relatively inexpensive fence. Despite the seeming absurdity of this material, a fence made from it turns out to be beautiful, plus inexpensive. More often, boards are laid horizontally, attached to support posts. And this is again savings due to the absence of lag.

All the advantages of a picket fence can also be attributed to a fence made of unedged boards. But, like all wooden structures, this structure is a fire hazard.

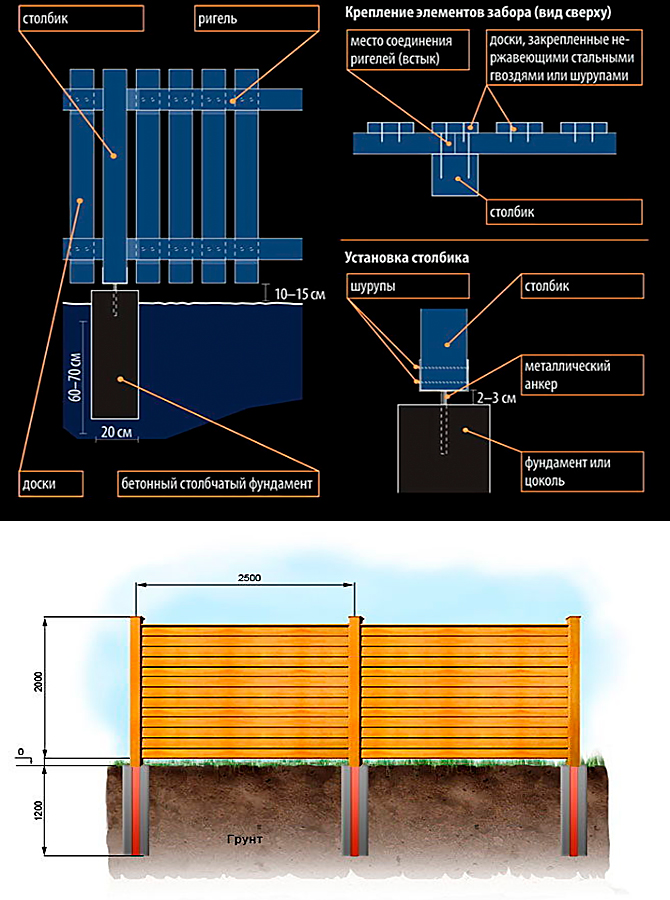

From boards horizontal

This cheap fence is an exact copy of the previous option. Only it uses edged boards laid horizontally. The option in terms of application is not new.

There are several varieties of it:

- a regular fence with gaps between the boards;

- solid;

- herringbone - laid in the form of a lining, that is, with the edges of the boards overlapping relative to each other;

- checkerboard - when the boards are laid in two layers with gaps so that the elements of one layer cover the gaps between the elements of the second.

From boards vertically

And this budget fence is a copy of the previous one with only one difference - the boards are laid vertically. At the same time, there are slightly more options for laying fencing elements. For example, a wicker fence, in the design of which the boards are arranged in the form of a vine woven between the joists. The original appearance has made the building quite popular today.

Gorbyl

This is a board with a flat surface on one side and a rounded surface on the other. The latter may be peeled or not peeled from the bark.This material is of no value for woodworking, so many consider it a waste. Typically, croaker, otherwise known as obapole, is used in the construction of secondary outbuildings: a barn, a chicken coop, and others. Formwork is often made from it.

This is a good option for a fence.

It is presented in two types on the market:

- Business. It is purchased for the construction of fences. He has a relatively decent appearance.

- Wood-burning. Low quality, a large number of defects and flaws, therefore it is used only for lighting boilers and stoves.

There are no special requirements in terms of choosing a slab based on the type of wood. The only thing is that you should not purchase birch and poplar flooring. The first quickly begins to warp, the second to rot.

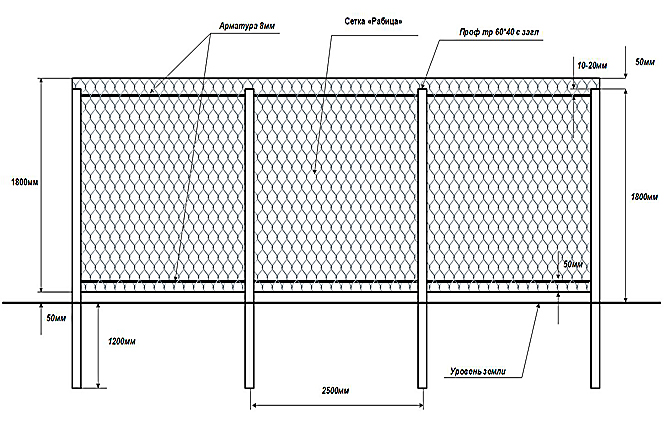

Rabitz

A well-known building material, popular with private developers. Typically, the mesh is used as a fence, which is installed around the perimeter of the site, except for the front side. Although some owners even install it from the facade.

The mesh can be attached to any type of support pillars: metal, wood, reinforced concrete. For fences, it is better to choose a mesh made either from galvanized wire or from wire coated with a protective polymer layer.

Scrim

This is another option for a cheap fence.It cannot be said that it is reliable in terms of protecting the site from intruders and animals, but as an alternative to other structures, a temporary option will do.

In addition to the mesh, one of the options for this type of fence includes: reinforcement with a diameter of 14-16 mm, which serves as posts, a cable with a diameter of 4-6 mm, replacing logs.

They make a fence like this:

- drive reinforcement into the ground every 2 m;

- stretch a cable in two or three rows between them, which is attached to the supports with plastic clamps;

- throw the mesh over the top joist so that it folds in two layers;

- fasten the edges of the latter to the lower joist with the same clamps or knitting wire.

For this fence option, it is necessary to use a camouflage mesh with a density of 75-90 g/m².

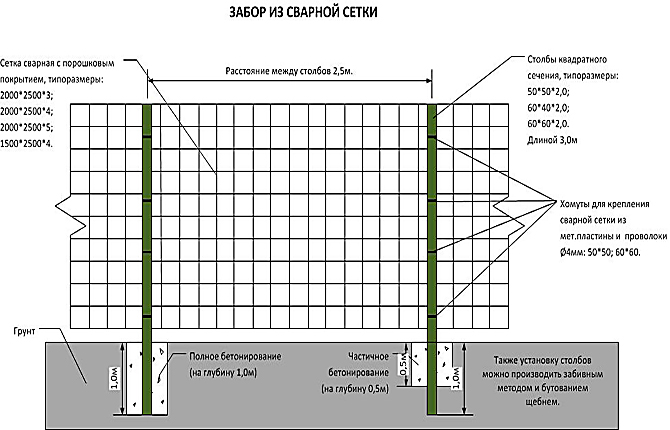

Welded mesh

This name hides a fence structure in the form of ready-made sections. They can be of different heights and lengths, made of wire or smooth fittings of different diameters. For production, wire made of black or galvanized steel, coated with a PVC layer of different colors, is used.

In terms of design, welded mesh has a fairly wide range, where it is necessary to highlight the so-called 3D option. It uses elements that are assembled into a three-dimensional structure.

This is not to say that such a fence is a cheap option. Metal is expensive, especially products made from it. But the advantages of the design largely outweigh this disadvantage:

- presentable appearance;

- The service life is unlimited if you take good care of the fence.

The disadvantages include the complexity of installation, where metal supports are required, which are filled with concrete during installation. Usually, a strip foundation is poured under such a fence, because the mass of the fence is too large. The sections are attached to the posts using screws and wide washers.

Concrete fence

This option cannot be called cheap. Today, sectional models are used for private plots. These are posts with grooves into which concrete sections are inserted. The latter can be different in height and design.

Euro picket fence

This material is now replacing the wooden picket fence. The reason is its merits. After all, a Euro picket fence is a narrow strip made of thin sheet steel. It is passed through a roller-type forming machine, where stiffening ribs are formed on the tape. Then the finished product is cut into panels (pickets) of the required length.

The technology is similar to the method of producing corrugated sheets, so many people think that a Euro picket fence is a profiled sheet cut into pieces of a certain width and length, which is fundamentally wrong.

A fence made from this material is an exact copy of the version made from a wooden picket fence. But with higher technical and operational characteristics.

Wicker fence made of branches

This option is an echo of the past. But life has shown that such fencing structures are still popular today. Many design companies offer them as an inexpensive fence that fits perfectly into the landscape design of country houses.

Branches or twigs are usually harvested in spring and early summer. They are cut from young trees. The bark is removed from them, and then they are dried. Before weaving, the blanks are immersed in water for 5-6 hours to make them easier to work with (they become flexible). Stakes made from the same rods, only of a larger diameter, are used as support pillars.

This fence option has an unusual appearance. It can be called cheap. In all other respects it is inferior to previous designs.

Today, companies involved in the production of plastic products offer rods made from polymers.Such a fence will last for decades and will not lose its original appearance.

From a profile pipe

These are welded products, usually sectional. Hence the huge variety of sizes, shapes and designs. The similarity to welded mesh is great. Simply, instead of wire or fittings, a profiled pipe is used. Hence the same advantages and disadvantages. These models cannot be classified as “cheap fences”.

Brick fence

This is definitely not a cheap design. It is difficult to build such a fence with your own hands, if the workman is not a specialist. Therefore, you will have to hire craftsmen who will work for many days. But brick fencing has many advantages over other models:

- if you take care of the fence in a timely manner, its service life is centuries;

- aesthetic appearance;

- compatibility with many building materials;

- relevance;

- does not rot;

- does not burn;

- a wide variety of design solutions.

A lot of weight can be added to the disadvantages, so a strip foundation must be poured under a brick fence.

Stone fence

A rare structure, but recently it has become popular. This is practically the same design as a brick one. Therefore, the advantages and disadvantages of a stone fence are the same as those of the brick version.

The only difference is the variety of stone types. Popular today:

- sandstone or limestone rubble;

- dolomite from the same rocks;

- cobblestone;

- boulder crushed stone;

- large pebbles.

Gabions

An original design solution that has recently become popular.Essentially, it is a wire mesh or a lattice made of smooth reinforcement, which is assembled into a box. A stone is placed inside.

It is not recommended to build gabions on unstable soils. But this problem is solved by pouring a reliable foundation under them, which increases the cost of the barrier structure.

Slate facade fence

Another option for an inexpensive fence for a summer house. Slate is a cheap material compared to other options for fencing. Since roofing material removed from the roof is usually used for the enclosing structure. Its price turns out to be zero. In addition, it is not difficult to install it yourself, although the weight of the slate is considerable. But a couple of extra hands makes the installation process easier.

As for the front part of the site, it is better to use flat slate for the fence. It is stronger and easier to paint. It will last for decades if you take care of the entire fence so that it does not collapse, sag, and so on.

Polycarbonate

A metal fence made of mesh or lattice or profiled pipe is most often used as a frame for installing polycarbonate. It is the metal that increases the cost of the fence, making it not cheap.You can also use a wooden frame, which will be cheaper than metal. But it doesn’t make the fence cheap either.

Hedge

A fence option that has always been popular.

As for the service life, if you plant plants instead of dried out, old and diseased ones, and properly care for the fence, then the fence will please the eye for more than one generation.

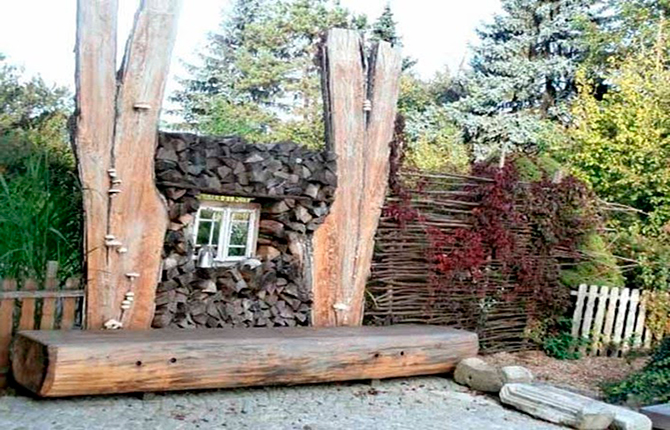

From scrap materials

Scrap materials are everything that remains on the site after construction or after reconstruction of a house.Or what has accumulated during the operation of the site. It is clear that there will not be enough materials of the same type for an entire fence. Therefore, it is worth choosing a combined option. But in any case, it will be a cheap fence made by yourself. For example, look at the photo below.

The picture clearly shows that the fence is made of different materials. And he looks good. Its elements were:

- firewood;

- old picket fence;

- network;

- old window;

- wood sawn lengthwise;

- flowers and plants.

You can add anything you can get your hands on: brick, stone, old slate, plastic bottles, etc. The main thing is to combine building materials correctly so that they create a single structure: beautiful, unusual, emphasizing the landscape design. This is one of the cheap options.

Made from PVC pipes

This design can be considered cheap if the plastic pipes are a remnant from construction. Today, many owners of private houses, when carrying out repairs, replace polypropylene pipes with products made from cross-linked polyethylene. You shouldn’t throw away the first ones; you can make a fence out of them.

To do this you need a soldering iron and scissors, as well as the ability to use these tools and imagination. Sizes, shapes and patterns depend on the amount of pipe used.

The advantage of a plastic fence is its long service life, at least 50 years.

From pallets

Pallets (pallets) are wooden products. Therefore, all the advantages and disadvantages correspond to wooden structures. This is a finished product, and accordingly it has a certain cost. But if you find used pallets, which are often used for kindling, then you can build a cheap fence with your own hands.Moreover, the construction process is not very complicated.

In essence, the structure of the fence is racks to which pallets are attached either with nails or self-tapping screws. In this case, the pillars can be made of any material.

After installation, the finished fence can be painted in any color or coated with clear varnish.

From bottles

Glass containers, as a building material, have been used by lovers of original solutions for a long time. It is not difficult to build a fence from it. And although a used bottle is a cheap product, a fence made from it turns out to be expensive. It's all about the amount of glass containers.

But there is an option that resembles a picket fence. It is several times cheaper than a solid fence wall. To do this, a structure from a profile pipe in the form of a rectangle is welded, the upper element of which is not installed. Pieces of smooth reinforcement are welded into the gap to the bottom. It turns out to be a kind of grid.

Glass bottles of different colors are placed on the rods. Holes are first made in their bottom using a gas burner. After assembly, the upper frame element is installed, which is welded to the sidewalls. The photo below shows this option.

And yet such a fence cannot be called cheap. The metal structure increases the cost. At the same time, glass containers are not the most reliable option for the street.

Option for a fence on a site with a slope

Any of the above options can be built on a site with a slope. The main thing is to carry out the construction processes correctly.

For example, a chain-link fence. Here:

- the posts are driven into the ground perpendicular to the surface, that is, not vertically;

- the mesh is attached to them in the standard way.

Such a fence itself will become inclined.She will perform her functions. But in any case, this is an ordinary cheap fence.

Another option is when the racks are formed taking into account the irregularity of the terrain. That is, they are installed vertically. But the material forming the fence is attached to them taking into account the slope - usually in the form of a stepped transition. A triangular opening is formed between the fence elements and the ground, as shown in the photograph.

There is no need to leave a gap, but then you will have to cut the bottom edge of the material at an angle. This option is suitable for picket fences, boards, slate, corrugated sheets and other materials that are used in the structure in the form of separate elements.

As for a powerful structure (brick, stone, etc.), a foundation must be built for it. On an uneven area there are three ways to do this.

Level the slope of the foundation area to the horizontal. There are three options here:

- cut the upper section to the level of the lower one;

- make bedding up to the top level;

- cut off half the length of the foundation, raise the second half with soil removed from the first part.

Another option is to create a stepped base for the foundation, which will also need to be poured in the form of a stepped structure.

Find out how choose a gate with a wicket for a private house.

Inexpensive options for painting a fence

Cheap painting means doing everything yourself, using an inexpensive version of paint, plus - doing without preliminary preparation of the surface to be painted. It will be necessary to take into account the tool for applying paint, because the consumption of paint and varnish products depends on it:

- The paint is applied with a brush in a thick layer, hence the high consumption.

- A paint roller reduces consumption.

- Spray gun - minimal paint consumption.

Cheap options include simple painting materials:

- Lime whitewash. Brick, concrete, stone, wood - all this can be painted with lime.

- You can weld the paint yourself, fortunately there are different ways, for example, Finnish technology.

- Serebryanka is also an inexpensive option.

- Minium mixed with drying oil. Both components are sold in hardware stores.

Fence height depending on the type of material

| Fence material | Fence height, m |

| Picket fence and Euro picket fence | Standard picket lengths: 1.5, 1.8, 2.0. To order: 0.1-5.0 |

| Corrugated sheet | Standard height – 1.7 The maximum recommended is 2.5 m. |

| Chainlink | Roll width, also known as fence height: 1.0, 1.2, 1.5, 2.0. |

| Boards | 2 |

| Brick, stone, blocks | Recommended - 0.5-3.0 |

The easiest way is with a cheap chain-link mesh. There are few requirements for such a fence in terms of height, which is determined by the width of the roll.

A corrugated fence has one requirement - the higher it is, the greater the windage of the structure. With strong gusts of wind, there is a high probability that the fence will collapse. Therefore, raising it above 2.5 meters is not recommended, but is not prohibited. In the latter case, you need a correctly carried out design calculation, plus high quality installation work. A high fence also requires not two, but three rows of joists, which increases the cost.

Stone structures also have requirements in this regard. The higher the fence:

- the thicker the base should be to ensure stability;

- more expenses;

- The construction process itself is more complicated.

Expert advice on choosing a fence

There are many nuances that you need to pay attention to when choosing the type of fence. Here are some of them:

- There is a desire to close yourself off from everyone and everything - then corrugated sheets.

- You need a ventilated fence - then a chain-link fence.

- An option that is not visible with a picket fence is strips installed on both sides of the joist in a checkerboard pattern.

- If the task is simply to mark the boundaries of the site - then a chain-link.

- If you want to install a classic design, there are a huge number of options.

When planning a fence for a summer house or a private home, you should first of all focus on your preferences, and only then on the cost of materials. But even a cheap fence, made with taste and imagination, can look much more interesting than an expensive one.

Which option from those described in the article would you choose? Write in the comments. Save the article to bookmarks and share it on social networks.

If the perimeter of the site is large, then even a chain-link will be an expensive option.

And I liked how they use the camouflage net. It's really cheap.

I agree, the mesh will be the cheapest. But how long will she last like this? How many years is enough for her? That's the question.

My plot perimeter is about 170 meters. The chain-link does not save you from dogs, cows, and is not a hindrance to cats at all. But I honestly didn’t expect such impudence from cows. The net was completely torn. The neighbor let him out and they walk wherever and however they want. They tore my netting, and they feasted on my second neighbor’s hedge. Options for fences vary in terms of labor costs and budget. But a profiled sheet in a frame with a concrete base (foundation) is the best option for me, taking into account that the site is on a slope.