Ball gas valve for underground installation: design and operational features

Timely isolation of the section of the gas pipeline where the accident occurred is necessary to promptly resolve the problem. In such situations, you cannot hesitate.Do you agree? Using a gas ball valve for underground installation, you can quickly and flawlessly shut off the medium transported through the gas pipeline.

Correct installation and proper use of the ball valve will help increase its service life and ensure high-quality and safe operation of the gas supply system. We will tell you everything about the design of this type of shut-off valve. Let's look at what the principle of its operation is based on.

The content of the article:

Features and purpose of ball valves

It is impossible to imagine the oil, chemical or gas industry without shut-off valves. Shut-off pipeline accessories, produced on modern high-tech equipment, will ensure the safety of the entire system.

Shut-off gas pipeline fittings - This is a mandatory design element. These devices are used both for external gas pipelines and for internal systems.

The purpose of ball gas valves is quite large:

- equipping complex systems through which aggressive and non-aggressive environments pass;

- use in pipelines located in hard-to-reach places;

- efficient operation in case of nominal pressure up to 16 MPa, etc.

When using ball gas valves, there is no need to create a manhole and enclosing structure.

If you need to dismantle any product, simply cut off part of the pipes.In this case, the shutter must be in the open position so as not to damage the locking ball. The valve design is not intended to regulate the flow of the pumped medium.

If it is necessary to install a limiting device on buried lines, then most often they use ball gas valves driven by an electric motor, gearbox or pneumatic cylinders. If the design has hydraulic or pneumatic drives, they can be controlled using external sources or the transported medium.

To do this, holes are made in the gas valve body through which the drive is connected. To prevent the structure from breaking, the spindle extension is protected with a shell in the form of a vertical tube.

Moreover, this tube is connected to the upper part of the valve body using a flange method. Most often, shut-off valves are installed directly where gas equipment is located.

In this case, for each source of gas consumption, an individual valve is installed, ensuring the sealing of a specific pipe. You can also install one additional valve with a ball valve at the inlet, which is responsible for completely stopping the gas supply. Such installation meets all the necessary requirements of the security system.

Gas ball valves ensure two-way movement of gas in the pipeline. Such devices can be mounted on gas pipes any diameter.They can be used on trunk networks, used in the operation of storage facilities and when transporting natural gas over long distances, etc.

Advantages of using a gas ball valve

A ball valve intended for underground installation is a device that is necessary to shut off the flow of gas in pressure pipelines laid in trenches.

These devices are used in both industrial and domestic environments. Gas valves provide quick and complete shutoff of the flow of the working medium. Their widespread use is due to their reliability, durability, strength and relatively low cost.

Ball valves are made of heavy-duty materials that are corrosion-resistant and inert to aggressive environments. The production uses alloys that can withstand all kinds of mechanical damage without problems or deformations.

The products have high wear resistance regardless of operating conditions. Ball gas valves are able to maintain their technological properties for a thousand (or more) cycles without malfunctions.

In this case, the temperature of the moving and the surrounding environment can be almost any. It has been experimentally established that gas ball valves can withstand temperatures from -60 to +80 degrees. Most gas taps can last much longer than the manufacturer claims.

The gas ball valve lock is made in a spherical shape and has a hole through which gas passes through the pipes. The diameter of the hole is selected in accordance with the dimensions of the pipeline. Adjustment of the throughput of the line is ensured by the ability to rotate the locking mechanism around its axis.

In the working position, the lock is located perpendicular to the pipeline, and it can be easily closed by hand by slightly turning the handle. When rotated 90 degrees, the side with the through hole changes to a solid surface.

With less rotation, the pipe will be partially blocked. But manufacturers do not recommend leaving the structure in a half-open state, because this contributes to increased abrasive wear of the device.

In intermediate positions, due to too high a flow rate of the pumped medium, the sealing seat rings can be completely damaged or partially deformed. This can subsequently lead to serious damage to the crane, its repair or replacement.

The product body is highly sealed. The use of metals and special alloys in the design helps reduce the weight of the structure. Such shut-off valves for gas pipelines can be safely installed in hard-to-reach places.

The use of high-quality gas valves with ball valves is beneficial from an economic point of view.These devices have a huge margin of safety and can fully function without needing replacement for many years.

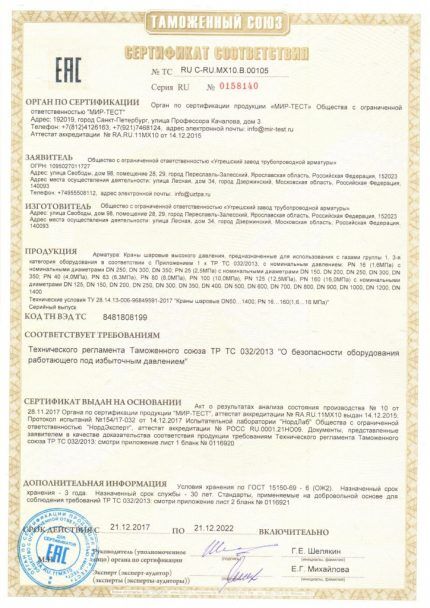

This is especially true for gas ball valves from well-known and trusted manufacturers. At the same time, you can verify the quality of any faucet by checking the certificates of conformity that confirm the quality of the products.

Typical design of a gas ball valve

Ball valves for underground installation of different brands have approximately the same structure. The design of products is determined by their performance characteristics and purpose.

A standard gas valve for installation on underground pipelines consists of:

- a sealed housing, most often made of brass or steel;

- a shut-off ball that subsequently shuts off the gas supply (because of this element the valve is called a ball valve);

- saddle, which is responsible for ensuring that the locking ball does not move anywhere;

- a section of connection pipe with a special thread, which is subsequently welded to the pipeline;

- the neck part necessary for the passage of the rod;

- extended connecting rod;

- washers contraindications;

- parts responsible for the tightness of the structure (o-ring, spring, ring and flange, made of soft and durable materials, for example, ethylpropylene rubber);

- handles made of strong material coated with polyvinyl chloride, thanks to which the entire product is controlled, and nuts that secure it;

- stopper or handle travel limiter.

In the production of product components, alloy and stainless steel are used, which have high anti-corrosion properties. Elastic fluoroplastic is used to seal the parts.Thanks to this polymer, the structure becomes waterproof.

Fluoroplastic ensures tightness of the coupling, smooth screwing and easy dismantling. This material is highly resistant to all kinds of aggressive environments, and its excess is easily squeezed out when the thread is tightened.

Due to the structural features, the closed position of the valve ensures complete sealing of the pipeline. The crane itself is small in size, which greatly simplifies its installation. During installation, both welded and threaded connections are acceptable.

In this case, the thread at the end of the pipe should not be longer than the thread of the tap, because otherwise, after tightening the threaded connection, the end of the pipe will rest against the O-rings, leading to premature damage to the valve.

The gas ball valve can be installed together with the pipe in any position, which in the future can guarantee maximum ease of use and quick access to the problem area.

Crane body for underground installation

The valve body is most often made of alloy, carbon and stainless steel or brass. Products made of brass are more expensive than faucets made of steel. But at the same time, both brass and steel do not corrode, due to which the service life of devices made from them increases several times.

Brass and alloy steel have a high level of ductility. However, they are not able to withstand strong and prolonged mechanical stress. For this reason, it is recommended to protect the locking mechanism from impacts and friction.

The design of the gas valve body itself depends on the following factors:

- production method;

- internal developments of a specific design bureau;

- the nature of the standards applied (TU, GOST, OST or any European directives).

The most durable, capable of holding any load, is considered to be an all-metal, non-separable body. It is first machined, cast into formwork using centrifugal force, and then welded using additional parts.

Also, the valve body can consist of two vertical halves or three elements. A dismountable housing made of 2-3 parts is more convenient for maintenance and can be used again after dismantling, but it is less airtight.

Ball valve bodies are also divided into full bore and pressure reduction. In the first case, the diameters of the tap and pipeline completely coincide, thereby ensuring minimal hydraulic resistance. In the second case, the log cabins are reduced by one standard size, so that the flow of labor can be controlled.

Regardless of the material from which the gas ball valve body is made, it must be coated with special protective agents against aggressive environments. Various chemicals are used for these purposes.

Firstly, these include acrylic paint, which has electrical insulating properties. It protects products from induced and stray currents. Secondly, in order to provide the faucet with anti-corrosion properties, it is coated with polymer paints and varnishes.

Thirdly, the body of the ball can be coated with epoxy-based coal tar paint. This paint is characterized by high anti-corrosion resistance and resistance to various mechanical damage. Fourthly, to protect the reinforcement during its installation without wells directly into the ground, a polyurethane foam coating is used.

Ball valve locking mechanism

When choosing a ball valve, special attention should be paid to its locking element - a ball or sphere. The ball should be smooth and shiny. Most often, the sphere is made of brass and coated with an expensive coating of nickel and chromium.

Checking the quality of the locking sphere is quite easy. To do this, you can check it with a magnet. If the magnet is attracted to the sphere, then this indicates that it is made of steel, which is intended for electrical use.

The steel ball of an underground gas valve quickly rusts and cannot be used for a long time in a humid environment. In this case, the brass ball will not be attracted to the magnet.

Gas tap handle

The convenience of its operation depends on the shape of the handle or handle of the ball valve. Most often, products with a handle in the shape of a butterfly (butterfly) or lever go on sale.The lever is more functional, so if possible, you should buy a gas tap with just such a handle.

The lever handle is especially convenient if the faucet has not been used for a long time and requires force to turn it. Gas taps are always available with green handles. It is not recommended to repaint them.

Types of ball gas valves

In modern gas pipelines they use gas taps the three most common types, classified according to the type of connection to the pipes. These are threaded, flanged and welded. Threaded or socket gas valves have a small diameter. Most often they are installed on gas pipelines for commercial premises, private homes and similar facilities.

The connection to the gas pipeline is made through a thread. The threaded connection between the gas ball valve and the pipe must not be overtightened, because This may cause the product body to break.

Flange valves are connected to pipelines in a flanged manner using bolts. Both threaded and flanged products are collapsible. Those. they can be dismantled, moved to another location and reinstalled at another point in the pipeline.

Welded valves are connected to gas pipelines by welding. Those. they cannot be disconnected from the pipes without damaging the structure. The diameter of the welded fittings varies from 10 to 70 mm. Welded gas valves are tight and reliable. They do not require regular maintenance, which is why they are very popular.

General operating rules

The basic rules for operating a gas tap are quite simple and predictable. The tap closes by turning the handle 90 degrees clockwise, and opens by turning it 90 degrees, but counterclockwise. If the handle is perpendicular to the axis of the faucet, this indicates that it is closed. The parallel position of the handle means that the tap is open.

The working environment passing through this valve should not contain overly hard elements or solid impurities that could damage the polished surface of the bolt ball. If solids can still get into the ball valve, a strainer should be installed in front of the ball valve.

The ball valve itself must be periodically opened and closed so that it can later be easily turned in any direction.

The ball valve should be operated using a standard handle. There is no need to use special levers for these purposes that can lengthen this handle. Opening and closing the tap should be done as slowly as possible to avoid water hammer.

The pressure and temperature at the installation site of the ball valve should not be higher than the operating pressure. Most designs do not allow the use of ball valves with the same temperature and pressure ratings.

The ball valve requires periodic cleaning of rust and dust, as well as tightening of the threads. In accordance with the manufacturers' recommendations, this should be done once every six months.

When installing pipelines, a pipe fastening design is provided that excludes the possibility of external mechanical influence on the valve, taking into account axial, radial or torsional loads.

Repairs and maintenance of a ball valve under pressure are prohibited. For full operation, the required section of the pipeline must first be cleaned. When cleaning the system, the ball valves need to be opened and closed several times.

How to spot a fake?

Before installing a gas tap, you must check its documentation of compliance with the specified pipeline and make sure that the device is not a counterfeit. Fake gas fittings are quite common on the market. When purchasing a gas ball valve, you should be careful to distinguish the original product from the counterfeit one. To do this, you can use some tips.

To deceive buyers, sellers can falsify accompanying documentation (certificates, declaration, product passport). Branded gas taps are slightly more expensive, so this kind of deception is common on the market.

The following signs also indicate a fake:

- Uneven surface of the faucet, on which microcracks and gaps are visible.

- Cloudy ball gap.

- Using silumin or zinc as the body material.

But it is extremely difficult to determine by eye the exact composition of the material used. For this purpose, numerous chemical analyzes are carried out. They cannot be done outside the laboratory under limited time conditions.

Therefore, when purchasing a ball valve, you should request a quality certificate for the product, a hygiene certificate or a declaration of conformity. In Russia, ball gas valves must comply with the requirements of GOST R 9544-2005 and GOST 21345-2005, 28343-89, 23941-2002. Certificates may also contain references to other regulations and quality standards.

Conclusions and useful video on the topic

The features of choosing a gas ball valve for underground work are described in the video below:

Any gas pipeline must be equipped with a reliable locking mechanism, especially if the pipes are laid below the surface. The valve is needed during an accident to isolate individual sections of the pipeline and to carry out repairs on the line in case of individual breakdowns. It will protect against threatening situations and catastrophic consequences.

Would you like to share interesting information on the topic of this article? Do you have information that is worth sharing with site visitors? Please leave comments in the form below, post photos, ask questions.