Transformer for halogen lamps: why is it needed, operating principle and connection rules

Halogen lamps can be considered an improved version of the usual incandescent lamps.They work the same way, but due to some features of halogens they are more economical, durable and produce a light that is pleasant to the eye, but at the same time bright.

Manufacturers offer two options for halogen lighting devices: high- and low-voltage. For the latter to work correctly, a transformer for halogen lamps is required. We will tell you how to select and correctly connect the specified device.

The content of the article:

Why does a halogen need a transformer?

Halogen lamps successfully compete with LEDs. Despite the better performance characteristics of the latter, it is often halogens that win, which is explained by their lower cost and, accordingly, availability, as well as some features of the light beam of LEDs, which can tire the eyes.

The main “trump card” of LEDs is operation without heating, which makes it possible to widely use them. Halogen lamps have the same advantage, but only for low-voltage lamps. They can be installed in areas sensitive to high temperatures. For example, in lamps built into the ceiling.

But you need to understand that low-voltage halogen lamps can only work with transformers. The latter are necessary to convert the mains voltage to an acceptable value for the lamp. Usually this is 12 V.

In addition, the transformer protects the light source from power surges, overheating and short circuits, and can also provide the ability to smoothly turn on the lighting. It must be admitted that, on average, lamps with transformers last much longer. Although a lot depends on their quality.

What types of transformers are there?

Transformers are devices of electromagnetic or electronic type. They differ somewhat in the principle of operation and some other characteristics.

Electromagnetic options change the parameters of the standard mains voltage to characteristics suitable for operation low voltage halogens, electronic devices, in addition to the specified work, also perform current conversion.

Toroidal electromagnetic device

The simplest toroidal transformer is assembled from two windings and a core. The latter is also called a magnetic circuit. It is made from a ferromagnetic material, usually steel. The windings are placed on the rod.

The primary is connected to the energy source, the secondary, respectively, to the consumer. There is no electrical connection between the secondary and primary windings.

Thus, power is transferred between them only electromagnetically. To increase the inductive coupling between the windings, a magnetic circuit is used.When alternating current is applied to the terminal connected to the first winding, it produces an alternating type of magnetic flux inside the core.

The latter meshes with both windings and induces an electromotive force or emf in them. Under its influence, an alternating current with a voltage different from what was in the primary winding is created in the secondary winding.

Depending on the number of turns, the type of transformer is determined, which can be step-up or step-down, and the transformation ratio. For halogen lamps, only step-down devices are always used.

The advantages of winding devices are:

- High operational reliability.

- Easy to connect.

- Low cost.

However, toroidal transformers can be found in modern circuits with halogen lamps quite rare. This is explained by the fact that, due to their design features, such devices have quite impressive dimensions and weight. Therefore, it is difficult to disguise them when arranging furniture or ceiling lighting, for example.

Also, the disadvantages of devices of this type include heating during operation and sensitivity to possible voltage drops in the network, which negatively affects the service life of halogen lamps.

In addition, winding transformers may hum during operation; this is not always acceptable. Therefore, the devices are used mostly in non-residential premises or in industrial buildings.

Pulse or electronic device

The transformer consists of a magnetic core or core and two windings. Depending on the shape of the core and the method of placing windings on it, four types of such devices are distinguished: rod, toroidal, armored and armored.

The number of turns of the secondary and primary winding may also be different. By varying their ratios, step-down and step-up devices are obtained.

The operating principle of a pulse type transformer is somewhat different. Short unipolar pulses are applied to the primary winding, due to which the core is constantly in a state of magnetization.

Pulses on the primary winding are characterized as short-term rectangular signals. They generate inductance with the same characteristic drops.

They in turn create pulses on the secondary coil.

This feature gives electronic transformers a number of advantages:

- Light weight and compact.

- High level of efficiency.

- Possibility to build in additional protection.

- Extended operating voltage range.

- No heating or noise during operation.

- Possibility of adjusting the output voltage.

Among the disadvantages, it is worth noting the regulated minimum load and the rather high price. The latter is associated with certain difficulties in the manufacturing process of such devices.

Rules for choosing step-down equipment

When choosing a transformer for halogen light sources, you need to take into account many factors.It’s worth starting with two important characteristics: the output voltage of the device and its rated power.

The first must strictly correspond to the operating voltage of the lamps connected to the device. The second determines the total power of the light sources with which the transformer will work.

To accurately determine the required rated power, it is advisable to make a simple calculation. To do this, you need to add up the powers of all light sources that will be connected to the step-down device. To the resulting value, add 20% of the “reserve” necessary for the correct operation of the device.

Let's illustrate with a specific example. To illuminate the living room, it is planned to install three groups of halogen lamps: seven pieces in each. These are point devices with a voltage of 12 V and a power of 30 W. Three transformers will be required for each group. Let's choose the right one. Let's start by calculating the rated power.

Let's calculate and find that the total power of the group is 210 W. Taking into account the required headroom, we get 241 W. Thus, for each group you will need a transformer, the output voltage of which is 12 V, the rated power of the device is 240 W.

Both electromagnetic and pulsed devices fit these characteristics. When choosing the latter, you need to pay special attention to the rated power. It must be presented as two numbers. The first indicates the minimum operating power.

You need to know that the total power of the lamps must be greater than this value, otherwise the device will not work.And a small note from experts regarding the choice of power. They warn that the power of the transformer, which is indicated in the technical documentation, is the maximum.

That is, in normal condition it will produce somewhere around 25-30% less. Therefore, the so-called “reserve” of power is necessary. Because if you force the device to work at its limit, it will not last long.

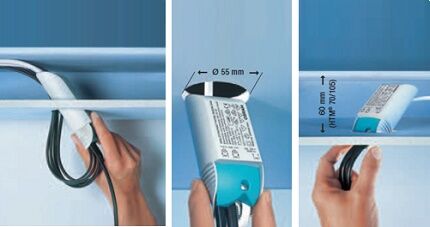

Another important nuance concerns the size of the selected transformer and its location. The more powerful the device, the more massive it is. This is especially true for electromagnetic units. It is advisable to immediately find a suitable place for its installation.

If there are several lamps, users often prefer to divide them into groups and install a separate transformer for each. This is explained very simply.

Firstly, if the step-down device fails, the remaining lighting groups will work normally. Secondly, each of the transformers installed in such groups will have less power than the common one that would need to be installed for all lamps. Consequently, its cost will be noticeably lower.

Two transformer connection options

Before connecting a step-down device, you should complete the layout of the lamps if there are more than two of them. In addition, you need to select the location for installing the transformer.

The latter is done taking into account the following rules:

- Free access to the device must be ensured, which is necessary for its maintenance or replacement.

- If the transformer is located inside a closed space, the volume of the latter cannot be less than 10 liters. This is necessary to remove the heat generated during operation of the device.

- The distance from the device to the nearest halogen lamp should not be less than 250 mm. This is done to avoid unwanted additional heating of the light source.

Only after the location for the transformer and lamps has been determined can installation and connection begin.

In this case, two main options are possible, and the latter can be modified and used to connect not only two groups of lamps, but also three or more.

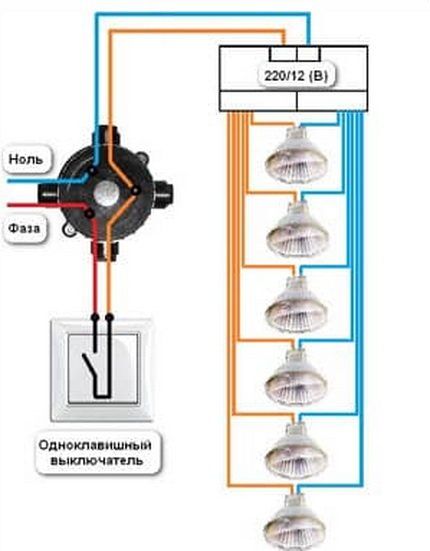

Circuit of lamps with one transformer

This option is considered optimal for four, maximum five light sources. If there are more lamps, it would be best to divide them into groups. Halogens are connected only in parallel. This must be taken into account when drawing up the diagram. Another important point.

It is necessary to place the lamps so that the distance from each of them to the transformer is approximately the same. This is necessary for the correct operation of the devices.

If there are wires of different lengths, the lamps will light differently. The one with a shorter wire will shine brighter. A device with a long cable will light dimly.

In addition, in the latter case, the wire may also heat up during operation, which is extremely undesirable.Experts recommend building the circuit so that the length of each of the wires leading to the lamps does not exceed 200 mm. In this case, the cable cross-section must be at least 1.5 square meters. mm.

On the transformer body there are output and input terminals. The primary ones are labeled N and L or Input. This is an input located on the 220 V side. It must be remembered that the connection here is made through a single-key switch.

Next, the neutral and phase wires of blue and orange or brown extending from the distribution box are connected to the corresponding terminals of the transformer. Halogen lamps are connected to the secondary Output terminals or the output of the step-down device.

For this, only copper wires with the same cross-section are used. Important note. If for some reason there are not enough transformer terminals, additional terminal clamps should be installed. They can be purchased at any specialty store.

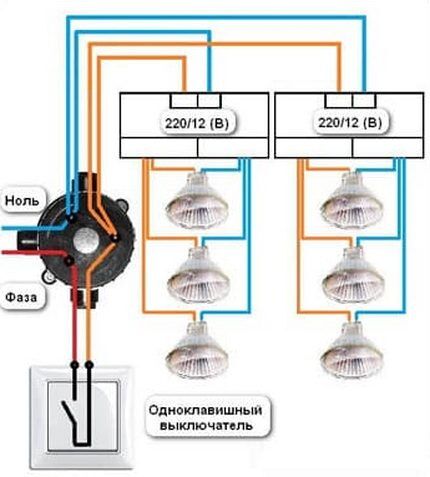

Two groups of lamps with two transformers

This connection is optimal if there are more than five lamps. Groups can consist of the same number of lamps or different ones. It doesn't matter. The main thing is that the transformer is selected correctly for each. As in the option described above, you should start by executing the diagram.

When choosing a location for lamps, similar rules apply. That is, the length of all wires extending to them from the transformer should be approximately the same.

This can be quite difficult to do. Then you will need to make some adjustments. You need to know that for copper wires with a cross-section of 1.5 square meters. mm, which is what is recommended to be used in this case, the optimal length varies from 150 to 300 cm. Over such a distance, energy will be transmitted with minimal losses and without interference.

Sometimes this length is clearly not enough. In this case, you will need to choose a wire with a larger cross-section. For a distance from 300 to 400 cm, a cable with a cross-section of up to 2.5 square meters is selected. mm. If an even greater length is expected, which is undesirable, a special calculation should be carried out and the appropriate cross-section determined using a special table.

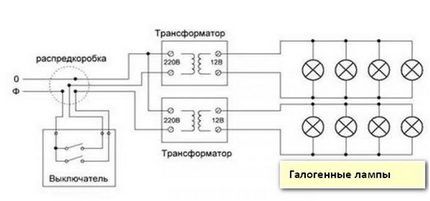

Connecting each of the transformers and groups of lamps to it is carried out similarly to the method described above. That is, the neutral core from the distribution box is connected to the neutral terminals of the transformers.

The phase conductor from the switch is connected to the phase cables of the step-down devices. Theoretically, more than two groups of lamps can be connected in this way, but each of them has its own transformer.

Important note. A separate cable is laid for each of the step-down devices, and they are connected exclusively inside the junction box. Some “craftsmen” prefer to connect the wires somewhere under the ceiling, but not use the junction box.

This is a serious mistake that contradicts the PUE, which states that free access must be provided to each of the cable connection sections for inspection, maintenance and possible repairs. Therefore, the only correct option is a connection in a junction box.

Experts emphasize that if you intend to connect a group consisting of a large number of lamps, it is possible to place a distribution box between the lamps and the transformer output. This is especially true if there are not enough terminals on the step-down device or if there are restrictions on its placement.

When choosing this option, you need to know that with the same power, a low-voltage circuit passes more current than a high-voltage circuit. Based on this, an accurate calculation is required to determine the cross-section of the wire. This is done by calculating the total current.

Let's illustrate with an example. Seven 12V 35W light sources must be connected via a transformer. The lamps are mounted parallel to the distribution box. Necessary to find out wire cross section, which will be laid between the distributor and the output of the block.

To do this, first multiply the number of light bulbs by their power. Then we divide the resulting value by the operating voltage. We get approximately 29 A. This is the current strength that will pass through the low-voltage wiring.

Using the table of the dependence of the wiring cross-section on the operating voltage presented in the PUE, we determine the appropriate wire size. In our case it will be at least 4 square meters. mm. As you can see, the load is quite large. Perhaps it makes sense to divide this group of lamps into two more.

When installing two groups of halogen light bulbs through a transformer, two types of switches can be used.If you install a single-key model, then both groups can only be turned on/off at the same time. If separate control of groups of lighting devices is required, you can install a two-key switch.

Recommendations from practitioners

Practicing electricians are often faced with the need to install low-voltage halogens when the wiring has already been installed and is being successfully operated. In this case, it is not always possible to parallel connect lamps to a transformer without radically altering the wiring.

To minimize costs, experts recommend in this case connecting each lamp with its own transformer. As a rule, these will be devices that are small in power and size.

If this seems wasteful, you can put high-voltage 220 V halogen lamps instead of low-voltage lamps. But in this case, you will have to equip them with a soft start device. Or, as an option, if the design of the lamp allows, you can replace halogen lamps with economy class LEDs.

With landmarks selection of halogens for the installation of a lighting system, you will find an article that thoroughly examines all aspects of the issue.

Very often it is planned to regulate the lighting intensity, for which purpose it is added to the overall scheme Dimmer. You need to know that most pulse transformers are not designed to work together with a dimmer.

Since the latter negatively affects the functioning of the electronic converter, this ultimately significantly reduces the service life of the connected halogen lamps.

For this reason, the best option for working in conjunction with a dimmer is a toroidal electromagnetic transformer. And one more note.

Electricians strongly recommend not to forget about servicing already installed step-down devices. It is optimal to carry out a routine inspection of them every six months to check their functionality. If problems are identified, the devices are repaired or replaced.

Conclusions and useful video on the topic

Video #1. Let's get acquainted - Osram transformers:

Video #2. How to properly connect a transformer:

Video #3. Everything you need to know about transformers for halogen light sources:

Low-voltage halogen lamps are a practical solution for recessed lighting. They are considered a budget analogue to LEDs, significantly superior to them in the quality of emitted light.

The main difficulty with using low-voltage halogens is the need to connect a step-down transformer. However, if everything is done correctly, the lighting fixtures will last a long time and without problems.

Do you have experience connecting a transformer to operate a low-power halogen light bulb? Do you know technological subtleties that will be useful to site visitors? Please write comments, share useful information, and post photos in the block below.