What is a precision air conditioner: classification of devices and operating principles of units

Do you think that in server and data centers, as well as other rooms where a huge number of computers and other equipment that intensively generate heat are concentrated, ordinary household air conditioners can be used to maintain constant temperature and humidity?

In rooms of this type, temperature, humidity and many other parameters must be maintained within a very narrow range, and conventional climate control systems, even the most powerful, cannot cope with this task. Therefore, the use of precision air conditioners is becoming increasingly relevant.

What distinctive features a precision air conditioner has, what it is in general, how it works and what types of these devices exist will be discussed in the article.

The content of the article:

Features of precision air conditioners

A precision air conditioner or an autonomous cabinet-type air conditioner is a device, the use of which allows you to maintain a number of parameters in a room: temperature, relative humidity and air mobility in a narrow range.

Namely:

- range of permissible temperature variability: ±1 °C. And certain models of precision air conditioners allow you to further narrow the variability of the value, up to ± 0.5 ° C);

- range of variability of the humidity value + 5%;

- Operation of the precision air conditioner is permissible at ambient temperatures ranging from +50 °C to -60 °C.

In this case, the released heat flux exceeds the values typical for the main room by 5–10 times. Accordingly, a very high load is created on air conditioners.

But still, the range of values is maintained. Indeed, in addition to the fact that this type of climate control systems is characterized by increased accuracy, a number of requirements regarding reliability are also imposed on the equipment.

Even a minute without air conditioning can cause catastrophic consequences. And, therefore, material losses.

Yes, there is one more requirement that cannot be ignored - precision air conditioners must be able to quickly start a backup unit in the event of a breakdown of the main one.

That is, even in the event of a force majeure situation, constant temperature and humidity conditions will be ensured. And the server room air conditioning project is usually drawn up taking into account additional capacities.

Benefits of using devices

The use of precision systems at various technological facilities is explained by the need to compensate for significant specific heat excesses that are released from technological equipment that is sensitive to even the most insignificant changes in temperature and humidity conditions.

That is, the greater the deviation of the room temperature from the optimal values, the more the service life of expensive equipment is reduced.

Failure to repair a breakdown of the climate control system in a short time can cause a breakdown of equipment that generates a significant heat gain.

For example, if the technological equipment in the telephone exchange room is overheated, as well as if there is an unacceptable deviation from the optimal value of the relative humidity value, the probability of equipment failure is quite high.

Precision air conditioners effectively compensate for significant specific heat excesses and make it possible to maintain the necessary temperature and humidity parameters in the room.

Scope of equipment application

The use of these devices to ensure trouble-free and trouble-free operation of process equipment is becoming relevant in the following areas:

- Fixed telephony - PBX stations, as well as equipment rooms.

- Mobile telephony – telecommunications nodes, meaning switches and gateways.

- Base and remote stations located in buildings or containers.

- Billing centers.

- IT sector – server and hardware rooms, as well as computer rooms and data centers.

Recently, precision air conditioners have also been used by pharmaceutical companies in areas where expensive diagnostic equipment is installed. And also in modern laboratories dedicated to conducting research with reagents that are especially sensitive to environmental conditions. Or - with colonies of microorganisms.

High-precision, clean production - the industry covers microelectronics, pharmaceuticals and aerospace, and is not complete without precision air conditioners.

But that’s not all - in some museums, libraries and other places of cultural leisure, where particularly valuable exhibits are stored, precision air conditioners are also used.

It’s clear that more budget models are used there, because there is no need to strictly observe the temperature and humidity conditions, but still.

Precision air conditioner device

The accuracy and reliability of the unit explains its complex structure. Moreover, depending on the model, it may differ.

The following is required:

- The indoor unit is usually a cabinet type.

- Outdoor or outdoor unit.

In the first, preliminary air preparation is carried out immediately before supplying it to the room.

The second may contain: an air condenser or a liquid cooler, if the air conditioner operates on cold water from a chiller or for a liquid condenser located in the indoor unit.

The above diagram is extremely simplified. It shows the operating principle in general terms.

Please note that in addition to all the listed parts, the indoor unit of the precision air conditioner includes the following devices:

- compressor;

- evaporator;

- throttle;

- filtration components;

- additional devices that use electricity for heating;

- humidifiers, if necessary;

- air fans;

- valves – both shut-off and control valves.

The presence of all other elements is determined by the specific model and the requirements for it and the room in which the device will operate. In other words, they are a variable component.

The mechanism of operation of the device

The basic principle of operation of this device can be explained as follows: first, the gaseous refrigerant is compressed in the compressor. The refrigerant then flows into the condenser. There it condenses, a process that makes it possible to remove heat from the refrigerant.

The next stage is the passage of the refrigerant, which is in a liquid aggregate state, through a throttling device. This leads to a decrease in the temperature and pressure of the liquid refrigerant.

And already in this state, the refrigerant enters the evaporator. There it turns into a gas and returns to the compressor.

So, it is the air blown through the evaporator that is taken from the room where it is necessary to maintain temperature and humidity in a narrow range of values.

Passing through the evaporator, the air is cooled, and in this form it again enters the room. The operating diagram of a precision air conditioner is shown in illustrative form above.

Indoor unit functions

They are determined by the purpose of a particular model. It is logical to assume that the number of functions determines the scope of possible application of the unit:

- cooling only;

- cooling and electric heating with the ability to regulate temperature conditions;

- cooling and increasing humidity.

The most perfect option is a combination of cooling functions, increasing humidity and electric heating.

It also happens that a certain model is manufactured by the factory according to an individual order, and functions that are not provided for in the original configuration are built into it.

Indoor units may differ in the types of air intake and supply into the room. For example, the pick-up can occur in the front part, and the feed in the top. It is carried out through an air duct located between the false and main ceilings.

There are other options:

- The intake occurring in the front part is combined with the supply in the upper part, directly into the room.

- In the upper part, the intake is carried out through an air duct located between the ceilings (false and main). The feed occurs, accordingly, from the bottom.

- The intake occurs in the upper part directly from the room, and the supply under the false floor is carried out from the lower part.

- The intake from behind and under the false floor occurs from the lower part, and the supply is carried out in the upper part through an air duct located between the ceilings - false and main.

It also happens that the fence is carried out under a false ceiling from the bottom and behind. The supply occurs directly into the room, at the top.

This variability of functions explains the wide capabilities of precision air conditioners.

The structure and mechanism of the selected model can be individually “tailored” to the characteristics of the room in which it is planned to be used.

Classification of precision air conditioners

Depending on the design of the indoor units, precision air conditioners are classified into the following types:

- ceiling;

- cabinet precision air conditioners;

- interrow.

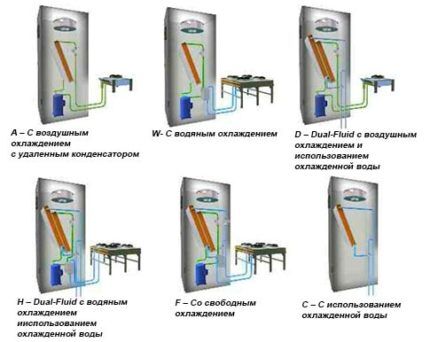

Depending on the method of cooling condensers, they can be air or liquid. Based on the classification, the coolant used is water or ethylene glycol.

Each of the categories listed above has its own characteristics, advantages and disadvantages, which must be taken into account when choosing a system for controlling the temperature and humidity conditions of the room.

Freon precision air conditioners

Freon monoblocks and precision climate control systems are provided for telecommunications facilities.

For larger stationary facilities, cabinet-mounted indoor units and row-by-row air conditioners are used.

The classic and most economical solution for server rooms in terms of capital costs are cabinet air conditioners equipped with a direct boiling evaporator, also known as freon air conditioners.

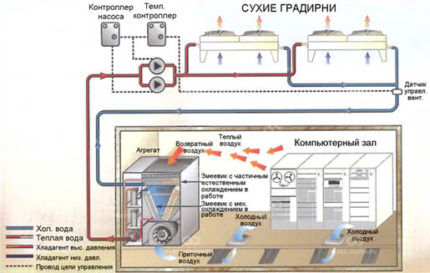

Various options for their design are possible: with an external air-cooled condenser, with a built-in liquid-cooled condenser, and also equipped with a dry cooling tower.

Inter-row air conditioners with direct evaporation (category coded as DX) also have similar types of condensers.

Liquid Precision Devices

Cabinet precision air conditioners equipped with a liquid heat exchanger are used in a cooling chiller circuit as closers.

In this case, operational reliability and cooling temperature conditions are determined by the accepted principle diagram of the object’s refrigeration supply - the diagram includes the presence chillers and pumping groups.

Start-up capital costs exceed by 30-40% the costs associated with freon air conditioners. It should be noted that optimization of the refrigeration supply scheme makes it possible to reduce operating costs.

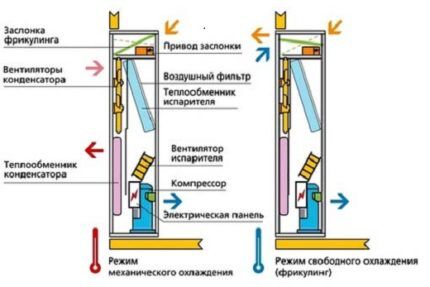

Precision air conditioner with free cooling

The functioning mechanism of this type of air conditioner is based on the use of reduced outside temperatures.

Free cooling (in English - free cooling) is easily and simply implemented in a freon precision cabinet-type air conditioner with a condenser (liquid) and a dry cooling tower.

You will need a 2nd heat exchanger (liquid) and ethylene glycol, which fills the dry cooling tower circuit. When the ambient temperature drops to the calculated level, cooling will occur due to the operation of the 2nd circuit - the heat exchanger and cooling tower.

Despite the increase in initial investments for the purchase of additional equipment, the payback period for these units will be less than 2 years, and a more accurate calculation can be made by knowing the size of local tariffs.

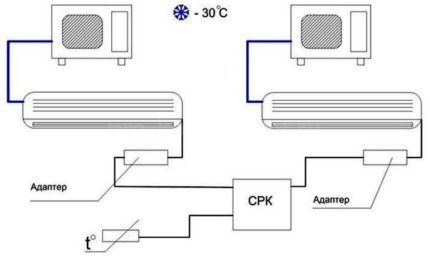

Features of reservation systems

To enable redundant cooling functions, precision air conditioners are equipped with additional heat exchangers—liquid and freon.

The basic principle of operation of this system is not simply the banal duplication of cooling systems, but the use of cooling systems with operating principles different from each other.

In other words, units equipped with different cooling sources are combined in one device.

The need for redundancy and its degree are established by regulatory requirements in accordance with the fault tolerance class of the object - determined by TIER.

Conclusions and useful video on the topic

The video shows the process of a master servicing a precision air conditioner with a step-by-step analysis of all the operating features of this device, as well as the requirements for its care:

A precision air conditioner allows you to maintain room temperature and humidity within a narrow range of values. This function is important in rooms where equipment that is sensitive to the slightest changes in climatic conditions is located and operates. This is why positional air conditioners are used in server rooms, data centers and high-tech laboratories.

Do you have experience working with this equipment, or do you have questions regarding the installation, selection or installation of precision air conditioners? Are there any problems with the functioning of precision air conditioners, complaints against manufacturers or service companies? In this case, be sure to share your comment below - you can be sure that your opinion will not be ignored.