Why the blender does not work: possible causes and do-it-yourself troubleshooting

Household appliances always break down at the most inopportune moment.For example, you urgently need to bake a cake for the New Year's table, and suddenly the blender stops working. In another situation, you can take it to a workshop, but in such conditions you have to deal with the problem yourself.

The content of the article:

Types of blenders

There are many instructions and recommendations to help repair household appliances. You just need to correctly diagnose the breakdown, disassemble and fix the problem. To start repairing a blender, you need to know its features; each has its own “weak” points. This makes it easier to understand why the device stopped working. Especially if you use the blender often and for a long time.

Blenders are divided into 4 main types:

- Submersible models. This is a hand-held device, in the handle there is an electric motor with a gearbox, onto which an extension attachment is attached. The knives are mounted on a shaft. The body (usually metal) has a protective skirt. The protection will prevent the blades from touching the walls of the container with food (fingers) if the blender is taken out, but the motor has not yet stopped working.

- Mentor models. The blender consists of a removable electric motor, a lid with a gearbox mounted inside, a shaft with knives and a set of glass containers.This is the only type of blender in which the shaft with blades has 2 support points - on the lid with the gearbox and on the support at the bottom of the container.

- Stationary blenders. Essentially, this is a housing with a motor and a planetary gearbox, onto which a glass container with a built-in shaft and knives is connected. These blenders are considered the most reliable. You need to try to make the device stop working.

- Combination blenders. The design uses elements of all the above models - a stationary housing and a cover with a gearbox. The model can work with dishes of various capacities and sizes.

There are also false models of blenders with a metal container, equipped with heating elements for preparing puree soups, cereals, and special foods for children and the sick. If such a device stops working, then it is better to contact a specialized workshop for repairs.

You can repair simple models yourself, for example, mounted or submersible ones. If your hand blender stops working, repairing it yourself will cost less than visiting a workshop.

We disassemble the blender depending on the cause of the breakdown

Repair work always begins with disassembling the device. The location and sequence are chosen depending on the reasons why the blender stopped working.

Mechanical failures that are easy to diagnose visually:

- Broken blade fastening.

- Damage or deformation of blades.

- The gearbox has stopped working, the blender motor hums, but the shaft does not spin.

Minor damage is also possible, for example, a broken shaft mount, a leaking seal, or a cracked container.

The most unpleasant cause of a breakdown can be considered the case when the electric motor stopped working.You need to disassemble it or check the condition of the speed controller. Most often, silence means that it is the engine that has stopped working. About half the time the blender is thrown away because of this.

If the motor stops working due to a short circuit in the windings or jammed bearings, then repairs will cost a little less than buying a new blender.

Replacing the knife

In most models, the cutting part (blades) is made of high-quality carbon steel with a hard chrome coating. Such knives can break before the gearbox stops working only if a large and hard object gets into the blender bowl.

Sometimes for hand-held low-power devices, knives are made of mild steel. It is believed that bent or broken blades are easier to replace than if the gearbox jams or the motor burns out. Then the blender will definitely stop working forever.

In stationary models, the knife is installed in the bottom of the bowl along with a gear coupling. The blades can be replaced as a block along with a coupling and gasket.

To do this you will need:

- Remove the cup, turn it upside down and place it on the table.

- Using a pin wrench (you can make it yourself from wire), unscrew the flange.

- Remove the knife block.

- Install the new one and screw the flange into place.

In order for the blender to work without beating, the knives must be accurately positioned according to the marks of the old block. If this is not done, the blades will stop cutting after some time, and a leak may appear under the seal.

Video: how to replace the blade in a blender

Video: blender shaft attachment

Knife repair on submersible models

For simple blenders, replacing the blade is more difficult. Typically, submersible models stop working precisely because of the destruction of the blade mounts.The petal with the cutting edge is simply pressed onto a tetrahedral (square) seat on the shaft, after which the end is flared.

Under load, the flaring breaks, the knives become loose, and the chopper stops cutting in one plane, and often cannot chop anything at all.

In order to secure the knives, you need:

- Use a file to cut off the flaring at the end of the shaft.

- Drill a 2.5 mm hole in the center of the shaft, to a depth of 8-10 mm.

- Cut the M3 thread and tighten the screw with washer.

Now you can change knives at any time. It is convenient to remove the blades to sharpen them on the machine.

Electrical related breakdowns

One of the reasons why the blender stopped working reliably is a stray contact. It could be a cord with loose pins, or the problem could be with the outlet itself.

If the blender stops working for no apparent reason, then it is not the motor or the speed controller. Most often, the malfunction comes down to a torn cord contact at the point of attachment to the electric motor brushes. The tear in the core can be soldered, or it is better to replace the entire cord.

Problem with speed controller

Most often, the device that regulates the speed of rotation of the knives is a rotary knob with a graduated scale or a pair of buttons on the body of the submersible apparatus. The blender speed controller is a board with several electronic components. Any violation of the operating rules, for example, with a “sparking” electric motor or a lost contact in the power cord, leads to the blender stopping working due to the burnout of the regulator board.

Sometimes a part is damaged during disassembly, but more often a powerful thyristor or transistor burns out.If there is a swollen capacitor on the board, then you can change it at the same time.

Another type of breakdown is when the blender stops maintaining rotation speed. The knives randomly accelerate and slow down until the motor stops working. The cause of such a breakdown may also be the blender buttons. Most often, touching leads to sudden acceleration, after which the device stops working.

If the blender stops: how to repair it

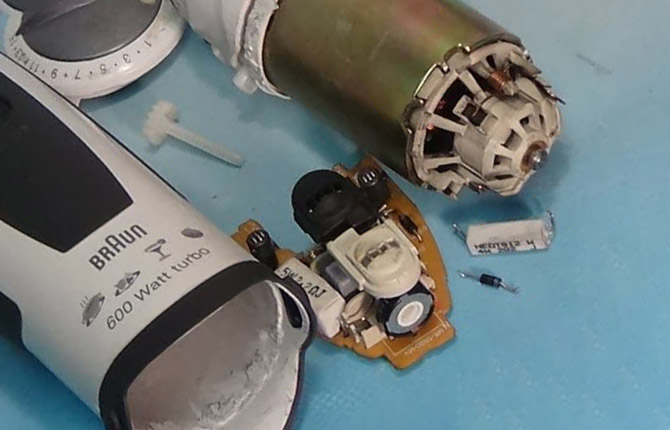

You can check the device only by disassembling it down to the motor and speed controller board. To do this, you need to remove the cover and cap covering the motor shaft with the compensating clutch. All that remains is to unscrew the screws and pull out the engine block.

Access to the electric motor allows you to solve most of the problems that cause the drive to stop working.

If you need to replace the silicone buttons (the motor works, but you can get an electric shock), you will have to open the back of the case. Remove the cover and unscrew the fastener. Access to the main control node is provided. Often in this way you can find a stray contact (not soldered) on the board, due to which the blender has stopped working stably.

Blender buzzes but doesn't work

If the device operates with a grinding noise, then most likely the gearbox needs to be repaired, the gears or the entire gear unit needs to be replaced.

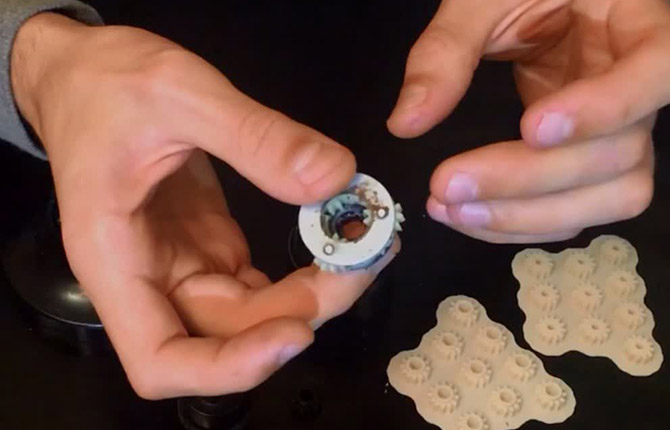

In stationary blenders, the reason the blender hums but the shaft has stopped rotating is the drive gear clutch. Since the bowl is removable, the torque is transmitted using a detachable coupling consisting of a bushing with teeth cut inside it and a gear wheel.

Each time the bowl is removed from the body, these 2 parts are unlocked, and accordingly, after the container is returned to its place, they engage again.The gap between the teeth is large. There are usually gear coupling kits available for sale for stand-up blenders. After disassembling the bowl, one part needs to be installed on the bottom, the second - on the gearbox shaft.

If after replacing the clutch the blender operates jerkily, then the problem is in the gearbox. Sometimes a situation occurs when the device stops working, but there is no time to buy a repair kit. In this case, the drive gear can be soldered with tin solder, or a temporary replacement can be made with a suitable homemade aluminum product.

No buzzing sound when turned on

If the blender does not make any sound, but power is supplied to it, then the cause may be the electric motor itself. More precisely, wiring or brushes. If, when you press the button, the motor does not work or jerks and stops rotating, then the brushes can be considered the cause.

It is not difficult to remove the engine itself. It is enough to unscrew the mounting screws with a screwdriver, release the shaft and remove the motor from the housing. As a rule, the models use electric motors from different manufacturers. But this is always a commutator high-speed motor with a power of more than 500 W.

The winding burns out with sparking and burning. Typically a short circuit occurs under load. As soon as you put the bowl on the clutch and turn it on, the motor stopped working with a bang. Such an engine needs to be changed, repairs will cost more.

If the electric motor jerks and “sparks” from time to time, then the reason is in the brushes. The first step is to clean the copper contact pads with a match or a wooden stick. Then wipe with alcohol and dry.

An old blender may stop working due to severe wear on the graphite brushes. In this case, you will need to disconnect the terminals on the brushes and remove them from the mounts. By marking you can determine the model and purchase new brushes.

Mechanical breakdowns

During operation, a polycarbonate glass bowl often gets cracked. Minor damage can be sealed with dichloroethane. If the length of the damaged area is more than 5 cm, the dishes need to be replaced.

Another problem that is often found in mounted models is that the shaft attachment with knives attached to the end rests on an additional support shaped like a protrusion at the bottom.

If the blender is overloaded, then the main part of the shock loads falls on the bottom support. As a result, the part chips or becomes cracked.

Since the support is inside the bowl, it cannot be glued. Such dishes can only be replaced.

Leaking engine gasket and bowl

In stationary models, the gasket often needs to be changed, even if the blender is working, cutting and chopping food with the same force as before. But since each time the bowl is installed on the gear coupling there is a small impact on the bottom, over time the gasket wears out.

A leak appears that needs to be fixed. Otherwise, moisture may get inside the housing and short-circuit the electrical wiring. To do this, you need to unscrew the bottom washer, remove the blade block and replace the gasket. If the leak is small, you can try simply tightening the nut more.

If you cannot find a gasket of the required size and thickness, you can make it yourself from thick paper. Replace the seals on the shaft of submersible models with silicone automotive sealant or any suitable gasket.

In submersible models, the sealing gasket is installed on the lower sleeve, immediately after the knives. Thanks to it, 2 problems are solved:

- The seal prevents liquids (juice) from entering the nozzle body.

- The rubber ring compensates for the runout of the shaft that transmits torque from the engine to the knives.

As soon as the shredder stopped working quietly, strong vibrations began to appear on the blades. This means it's time to change the rubber gasket. To do this, you need to press the shaft out of the upper and lower bushings, insert a new oil seal inside and forcefully press the shaft into place.

If the vibrations do not disappear or the blender stops working quietly (metal rattles appear), then the upper bushing needs to be replaced. Often both bushings are tinned with tin in order to reduce the mounting size of the holes and eliminate runout.

The latch mechanism is faulty

The bowl fixation system is used only on stationary models. Any latch consists of a plastic pressure lever, a spring and a rotation axis. Usually, with frequent use, only the spring wears out or breaks. As a result, the bowl warps, the safety limit switch is triggered and the motor stops working.

In this case, you need to squeeze out the axle with tweezers and pull out the lever with the spring. Often the latch simply becomes clogged with dirt. Half the time you have to change the spring to get the blender to work.

If the device stops working due to a broken latch, it is better not to operate the machine. This is unsafe and without reliable fixation of the bowl, the wear of the gear coupling greatly increases.

It often happens that the shredder stops working for several reasons, with one breakdown being the result of a malfunction of another unit.

Gearbox repair

The most unreliable part of stand-on and immersion blenders is the planetary gearbox. Structurally, the gearbox is a round box, inside of which the following are installed:

- Large diameter central gear.

- Three small gears are satellites linked to the wheel.

- Central gear mounted on the motor shaft.

It is this gear that is subject to maximum wear and shock load. If the blender stops working stably, the attachment shaft rotates with a grinding noise, this means that the central gear is worn out and does not transmit torque to the satellites.

To repair, you need to remove the block with the shaft and the central gear mounted on it from the housing.

Use pliers to remove the damaged part from the shaft. Buy spare parts for repairs in advance. If the blender does not work, then it is better to show the gearbox in the store to buy a repair kit of the right size.

Using a light (50 g) hammer and a wooden block, drive the gear onto the shaft. Lubricate it with grease (solidol or cyatim) and install the shaft assembly in place. The block may need to be glued into the blender body.

We definitely check how the blender works after repair and whether it has stopped making grinding and noise.

Even if the blender stopped working at the most inopportune moment, nothing bad happened. Most breakdowns are relatively easy to fix on your own. The tool that is in every home is enough. An exception may be cases when the device is under repair, or there is no suitable repair kit.

Video: how to disassemble a blender

Video: blender repair

Tell us about your own experience in repairing blender grinders. How difficult was the recovery process? What problems had to be solved to get the device working again?

I can tell you how to check the engine before purchasing or after repair. Turn it on at idle, without load, and turn the engine for up to 40-50 seconds. Then you test the housing with your hand; if you hear it hot, it means the engine is assembled incorrectly and will most likely burn out in the future.

I've never repaired blenders, but I had to. There is no point in buying a new one; old models last for 20-25 years, and new ones for 3-4 years. My advice is not to glue the body parts together. We will have to sort out the problems. Any fastening is only mechanical. Still, due to vibrations, the glue bounces off.

The clutch of the motor block of the ETA spesso 2015 blender has malfunctioned. Excellent blender, bought in the Czech Republic. The Internet and specialists (5 people called) did not help. I looked at the information on OZON (photos and characteristics of similar parts) and took the risk of ordering - “Coupling for the motor block of a blender brand Gorenje 534819.” Cost 349 rubles. It arrived within 10 days.

ONE TO ONE!!!

Maybe the information will be useful to someone.