Composition of concrete for paving slabs - home manufacturing technology

Paving slabs and paving stones are popular road materials that not only allow you to form alleys, platforms and other territorial areas. With their help, you can save money by carrying out all the processes yourself. The composition of concrete for paving slabs differs from the classic one from which all other building structures are poured.

The content of the article:

Technologies for manufacturing paving slabs

The main ones are vibration casting and vibration pressing. The first is making a solution and pouring it into molds that are installed on a vibrating table. The latter got its name only because it vibrates with a small amplitude. This allows the concrete solution to be shaken and made denser, which makes the finished product denser.

The second technology is based on pressing the mixture, which is placed into molds. For this purpose, special equipment is used, the use of which increases the cost of paving slabs. But it is this method that saves cement through the use of a semi-dry method. That is, the solution is mixed with a low water content. In addition, tiles and paving stones made by vibration pressing have higher strength and geometric dimensional accuracy.

But, since the task is to produce paving slabs with your own hands, we will have to talk about the first technology - vibratory casting.

Types of solutions

The composition of paving slabs consists of two layers: front and base.They are made from two different concretes. A reinforcing frame is laid between them. This can be an ordinary steel mesh or hand-woven pieces of wire.

Concrete pouring process:

- the solution for the front layer is poured into the mold;

- carry out vibration on vibrating table;

- lay the reinforced frame;

- pour the concrete of the base layer;

- vibration starts again.

No more than half an hour should pass between pouring two different types of concrete. If this happens, then there is a high probability that the paving slabs will simply delaminate during use.

To prevent this from happening, you need to be well prepared for the process of making paving slabs. Namely:

- choose two containers in which two different types of concrete will be prepared;

- cut the mesh into pieces the size of which corresponds to the size of the molds.

After this, you can proceed to the preparation of concrete compositions.

Facing solution

The front surface of paving slabs is constantly exposed to loads during operation. Therefore, it should be the strongest and most wear-resistant plane.

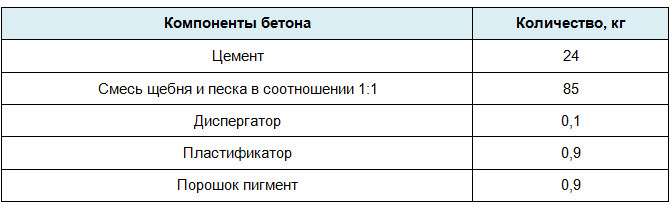

This layer should include high-quality materials:

- cement grade not lower than M500;

- a mixture of crushed stone and sand in a 1:1 ratio, which includes medium-fraction gravel (5-10 mm), sand - preferably river sand;

- water;

- dispersant;

- pigment.

Such concrete is poured into molds in a layer 2 cm thick and vibrates for 2-4 minutes.

Dispersant solution

This is a chemical substance that belongs to the category of surface-active plasticizers. It is added to paving slabs made from concrete to achieve certain product characteristics:

- the front surface is strengthened;

- it becomes glossy;

- the tiles are easily separated from the mold;

- no concrete particles remain on the surfaces of the forms, which reduces cleaning costs;

- concrete becomes more mobile and plastic, which simplifies working with it;

- the color of the paving slabs becomes more pronounced.

The dispersant itself is a white powder. But it is added to concrete only in the form of an aqueous solution. It is prepared in a ratio of 1:4 (reagent-water). The latter should be warm – +50 ℃. The amount of dispersant solution in concrete is 1 liter per 50 kg of cement. Manufacturers guarantee that the prepared aqueous solution can be stored for 5 days without changing its technical characteristics.

Concrete dispersant is an active chemical substance. Therefore, when working with it, it is necessary to strictly adhere to safety rules: protective gloves on your hands, glasses on your eyes, a mask on your face.

Making paving slabs with your own hands. You can read about this Here.

Example of mixing a mixture for a surface layer

The composition is mixed in the following sequence:

- First, the gravel mixture is mixed with cement in a ratio of 2:1. But first of all, half of the crushed stone with sand is added to the composition. After thorough mixing with cement, the second half is added.

- Water is pouring in. The solution is mixed.

- A dispersant is added, pre-mixed with the required amount of water.

- A pigment is added, which is also pre-diluted with water. Usually this is 1 liter. The amount of dye should not exceed 5% of the volume of the total concrete being prepared.

The material is stirred until it reaches a creamy consistency and the pigment colors the mixture evenly. But not less than 10 minutes.If the color of the solution is not satisfactory, then there is still time to make adjustments - make it more saturated or dull. That is, add pigment or other components accordingly.

As soon as the concrete for the front layer of paving slabs is ready, it is poured into a clean container. There is no need to use the mixture right away or pour it into molds. It is necessary to prepare a second solution.

Base layer solution

It differs from the previous one:

- no pigment is added to the composition;

- instead of a dispersant, you can use a cheaper plasticizer or a thick detergent, such as shampoo;

- the ratio of cement to crushed stone-sand mixture is 1:3.

An example of preparing a mixture for the main layer

Before mixing, it is necessary to wash the insides of the concrete mixer drum. You can just pour water and twist it. There is no need to drain it. The cement and gravel mixture is poured directly into the drum.

After a few minutes of work, add plasticizer dissolved in water, if purchased in powder form. If it is a liquid, then it is poured straight from the container. Here it is important to strictly follow the quantity to be filled, which the manufacturer indicates on the packaging. You should not reduce or increase it - this will lead to changes in the characteristics of concrete.

While the material for the base layer of paving slabs is being mixed in the drum of the concrete mixer, you can begin to pour the solution for the face layer into the molds. The pouring thickness is 2 cm. After which the vibrating table is turned on for 3 minutes.

Concrete compaction has occurred. The vibration table turns off. A reinforcing mesh is laid on top of the concrete. The finished concrete composition for the main layer of paving slabs is poured from the concrete mixer drum into a container. It is placed with shovels into a mold, where there is room for the solution.The mixture needs to be laid a little more, because after vibration and compaction the material will “settle”.

The vibrating table turns on again and works until the concrete in the forms is level with their edges. At this moment, air comes out of the cement-gravel composition, which, after the concrete hardens, reduces its quality characteristics: strength and wear resistance. It's all about the air bubbles remaining inside the solution. They reduce the density of the mixture, and, accordingly, the strength of the entire structure.

Total material consumption

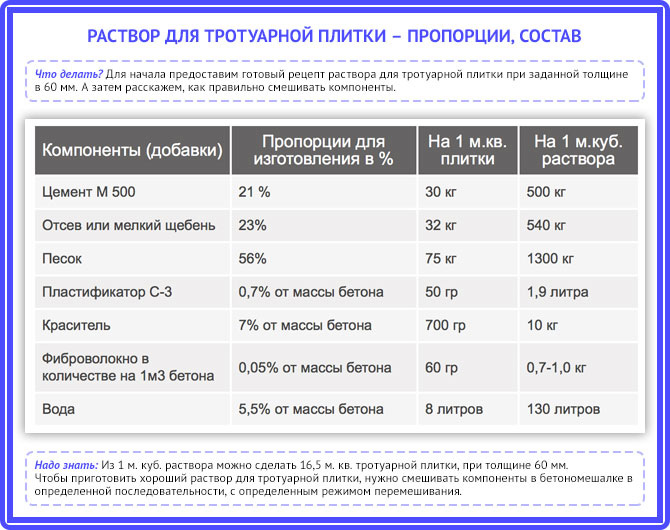

There are clear standards for the consumption of concrete components for the preparation of paving slabs 5 cm thick per 1 square meter.

The volume of dye can be changed depending on your preferences. The more it is added to the composition, the brighter the front surface of the paving slabs.

What affects quality

The quality of building materials depends on two factors:

- quality of ingredients used;

- exact sequence of technological operations.

Regarding the building materials used in the composition of concrete, cement of a grade not lower than M500 is taken. It is better to take washed and sifted river sand. Crushed stone fraction 5-10 mm, but washed.

There are also requirements for water. It must be clean, without impurities or debris. Ideally, it contains a small amount of salts, which make it hard.

The concrete mixing sequence described above must be followed exactly. This applies not only to the proportions of building materials added, but also to the time of the process itself. The pouring of the composition in layers must be strictly maintained. If all recommendations and standards are followed, this guarantees long-term operation of paving slabs.

Have you ever mixed concrete for paving slabs yourself? What lineup did you have? Write in the comments. Share the article on social networks and save it in bookmarks so as not to lose it.

Watch the video to see the process of making paving slabs with your own hands. Preparation of the solution, its composition and ratio of components. Forming and vibrating molds, laying filled molds.

Sources:

- https://protrotuarnujuplitku.ru/trotuarnaya-plitka/izgotovlenie-rastvora.html

- https://betonopedia.ru/beton/sostav-dlya-trotuarnoj-plitki.html

- https://masterskayapola.ru/trotuarnaya-plitka/rastvor-proporcii-sostav.html

Instead of mesh, you can put fiber fiber into the concrete. The strength is excellent.

There is nothing better than a steel frame, especially if the tiles will work on the road under a car. Instead of mesh, you can use used wire. And you have to pay for the fiber.